I. What Is Make to Order (MTO)?

Make to order (MTO), or made to order, is a popular approach in supply chain management, that typically allows consumers to purchase products that are customized to their specifications. It is a manufacturing process in which the production of an item begins only after a confirmed customer order is received. The main goal of MTO is to reduce inventory costs and waste by producing goods only when there is a demand for them In this blog post, we will explore what make-to-order is and how it is implemented in the SotaERP supply chain management system.

Inventory plays a vital role in the operations of manufacturing businesses. For many, revenue largely stems from selling merchandise and products. However, maintaining inventory also presents significant costs within the manufacturing process. This is because manufacturing facilities must store raw materials, components, work-in-progress items, tools, and finished goods, all of which incur additional expenses.

Effective inventory management strategies are necessary to strike a balance between the costs associated with inventory and the desired level of customer service and satisfaction. One approach manufacturers can take to manage inventory levels is selecting a production method that best suits their organization.

Two common methods are make-to-order and make-to-stock. While each has its pros and cons, it's crucial to ask pertinent questions when deciding on the optimal production and inventory control approach for your business. These questions might include:

- What is the production lead time for your products?

- Are your customers geographically distant, necessitating longer shipping times?

- How costly is it to store excess inventory in warehouses?

II. Benefits of Make-to-Order strategy

- Reduced inventory holding costs: MTO helps minimize the need for maintaining a large inventory of finished goods, reducing storage costs and the risk of obsolete inventory.

- Increased customization: MTO enables companies to tailor products to individual customer requirements, enhancing customer satisfaction and potentially increasing sales.

- Improved demand forecasting: By directly linking production to customer orders, MTO can provide valuable insights into customer demand patterns, allowing for better forecasting accuracy.

- Lower risk of overproduction: MTO helps mitigate the risk of producing excess inventory that may not be sold, thereby preventing waste and improving overall operational efficiency.

- Improved Cash Flow: MTO often involves pre-payment from customers, leading to a more predictable cash flow for the business.

- Greater Flexibility: SotaERP allows for easy adaptation to changing customer demands and product modifications.

III. Challenges of Make-to-Order strategy

Although implementing MTO will bring many benefits in the supply chain management process, there are also some challenges that businesses may face. Include:

- Longer lead times: MTO processes typically require additional time for production and procurement, as products are manufactured based on specific customer orders. This can result in longer lead times compared to other manufacturing strategies.

- Complex production planning: Coordinating production schedules and ensuring timely delivery of customized products can be challenging. Efficient production planning and scheduling systems are necessary to optimize resources and meet customer requirements.

- Increased dependency on suppliers: MTO relies on timely and accurate supply of raw materials and components from suppliers. Any disruptions or delays in the supply chain can impact production and delivery schedules.

- Cost considerations: MTO may require additional setup costs, such as configuring production lines for customization or investing in flexible manufacturing technologies. It's essential to carefully assess the cost implications and ensure the pricing strategy aligns with the value provided to customers.

IV. How to utilize MTO Strategy in SotaERP System.

In SotaERP's Warehouse Management module, the "Make to Order" (MTO) functionality allows you to automatically generate manufacturing orders or purchase orders when products are ordered by customers but are not currently in stock. Here's how you can set up "Make to Order" in SotaERP:

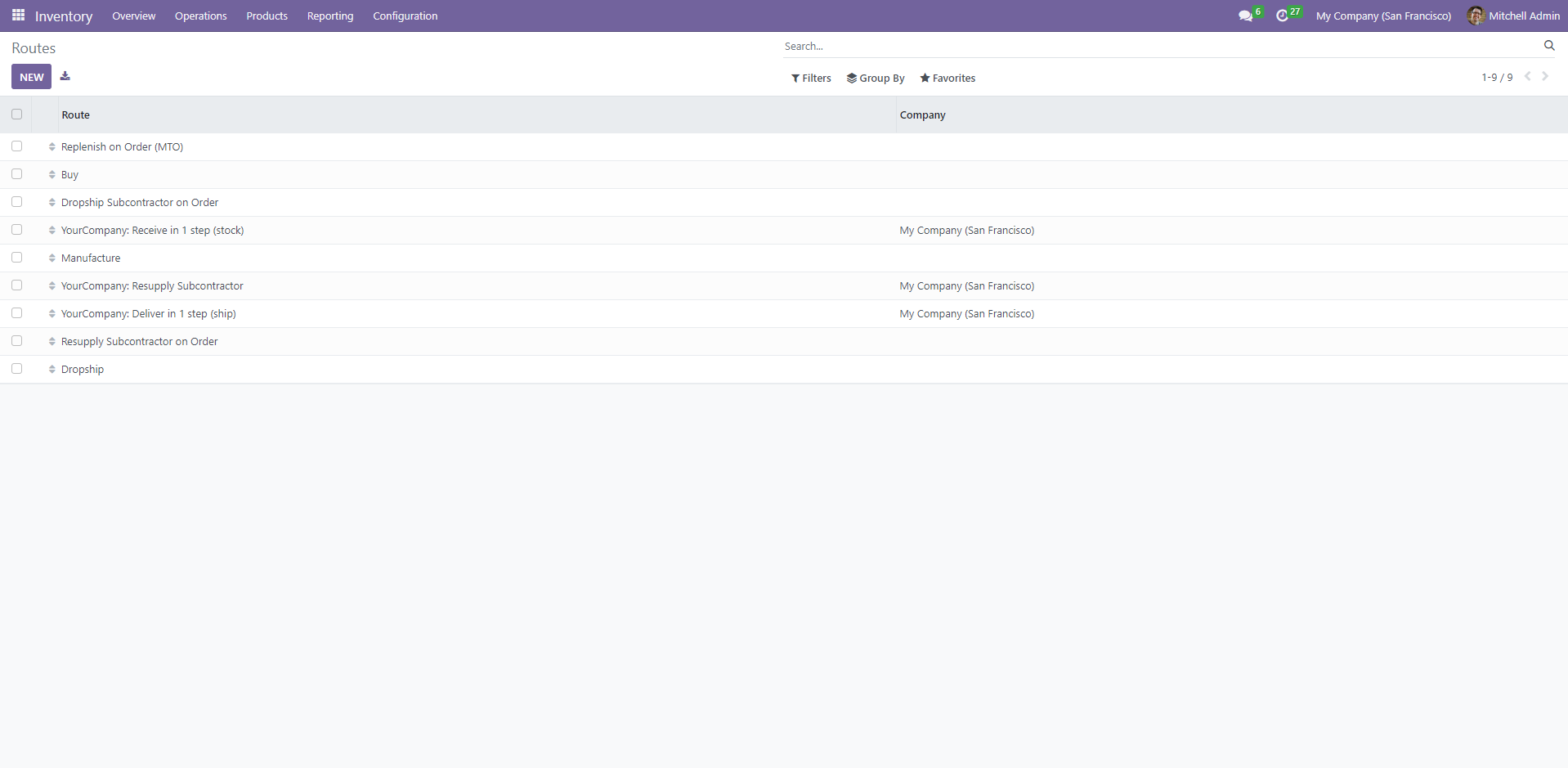

Step 1: Configure Procurement Rules:

- Navigate to "Inventory" > "Configuration" > "Routes."

- Select the route "Make To Order."

- Assign this route to the product(s) you want to manage with Make to Order.

- This ensures that when the product is out of stock, a procurement order will be automatically created to fulfill the customer order.

>>>> See More: All about replenishment rules: Make to Orders, Minimum stock, Forcast and more.

Step 2: Enable MTO in Product Configuration:

- Go to the "Inventory" application.

- Select "Products" from the menu.

- Choose the product for which you want to enable Make to Order.

- In the product form, under the "Inventory" tab, check the box for "Make To Order."

- SotaERP allows you to automatically generate manufacturing orders or purchase orders when products are ordered by customers. You can combine MTO and Manufacture routes or MTO and Buy routes.

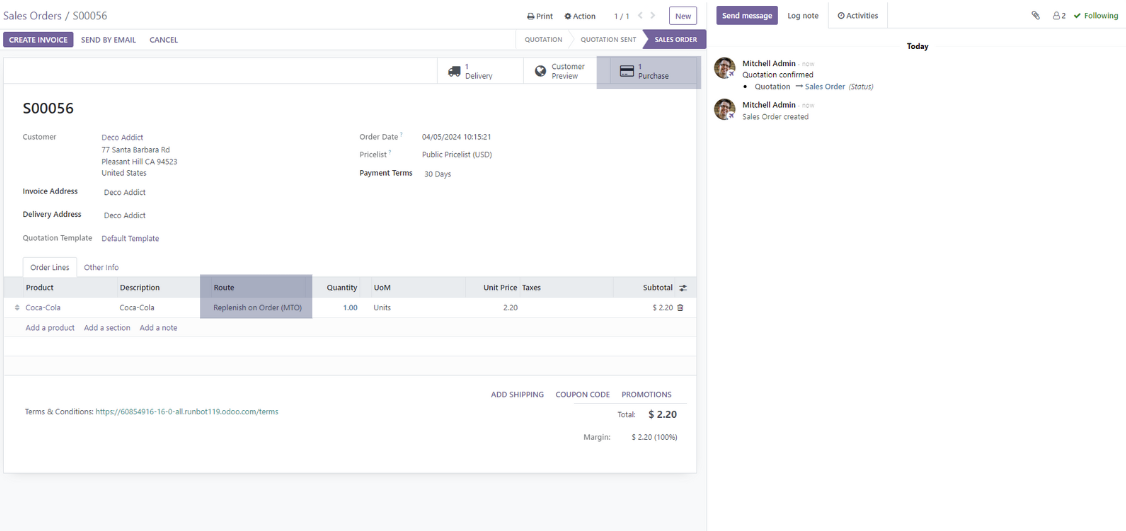

Step 3: Create a Sales Order:

- Go to the "Sales" application.

- Create a sales order for the product that is set to "Make to Order."

- When confirming the order, SotaERP will check the stock levels.

- If the product is not available in stock, it will automatically generate a manufacturing order to produce the required quantity.

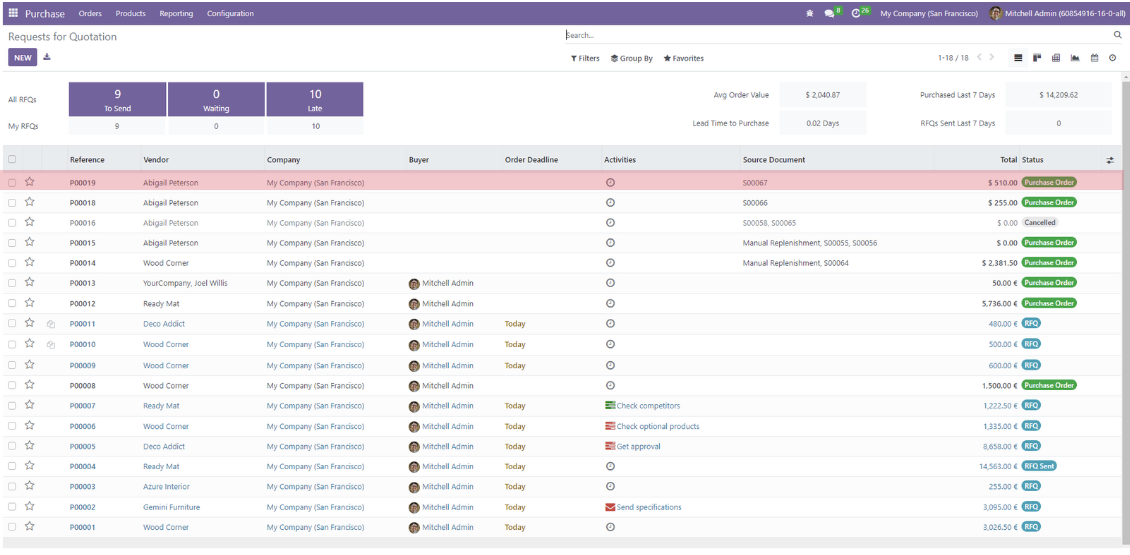

Step 4: Automatic Generation of Purchase Order or Purchase Order

- In the "Purchase" application, you'll find the automatically generated purchase order.

- Review and confirm the purchase order to start procurement process.

- Once the procurement process is complete, the product will be available in stock to fulfill the customer's order.

Automatic Generation of Purchase Order based on Make to order rule in SotaERP

By following these steps, you can effectively implement the "Make to Order" functionality in the warehouse management of SotaERP system, ensuring that products are procured or manufactured only when there is demand, thus optimizing inventory levels and production efficiency.

V. Conclusion

Make-to-Order strategy offers several advantages in supply chain management, including reduced inventory carrying costs, minimized risk of excess inventory, and improved responsiveness to customer demand. SotaERP's comprehensive suite of applications provides robust support for implementing and managing Make-to-Order processes efficiently within the supply chain.

Leave us a message!