Challenges that packaging manufacturers have to face off

As a packaging manufacturers, you have to face off plenty of problems everyday such as:

- How to deal with lack of material

- Arise of material cost

- Lack of information about production

- Late delivery

- Hard to control quality of every process in the production lines

- Various types of products

- Hard to calculate exactly production cost, margin

- Complicated production procedures

From these problems, we have been developing a solution for packaging manufacturers to manage their production more effectively.

What does ERP solution cover?

Sales

Sales and other activities

Quotations and sale orders

Easy to create quotations and convert them to sale orders

CRM

Manage all your clients' importation and your sale opportunities

Website builder

Build a beautiful and professional website with powerful tools

Manufacturing

MRP, Inventory and manufacturing

MRP

Schedule your production and material requirements

Manufacturing

Define BOMs, production zone, monitoring production process

Inventory

Inventory in real time, quick action with barcode

Human resources

Employee, payroll...

Employee

Employees' information and contracts

Payroll

Create payroll automatically

Approvals

Automate approval process

Account

Finance & account

Invoicing

Issue and manage invoices

Account

Manage accounts with full reports

Expenses

Create and approve expenses

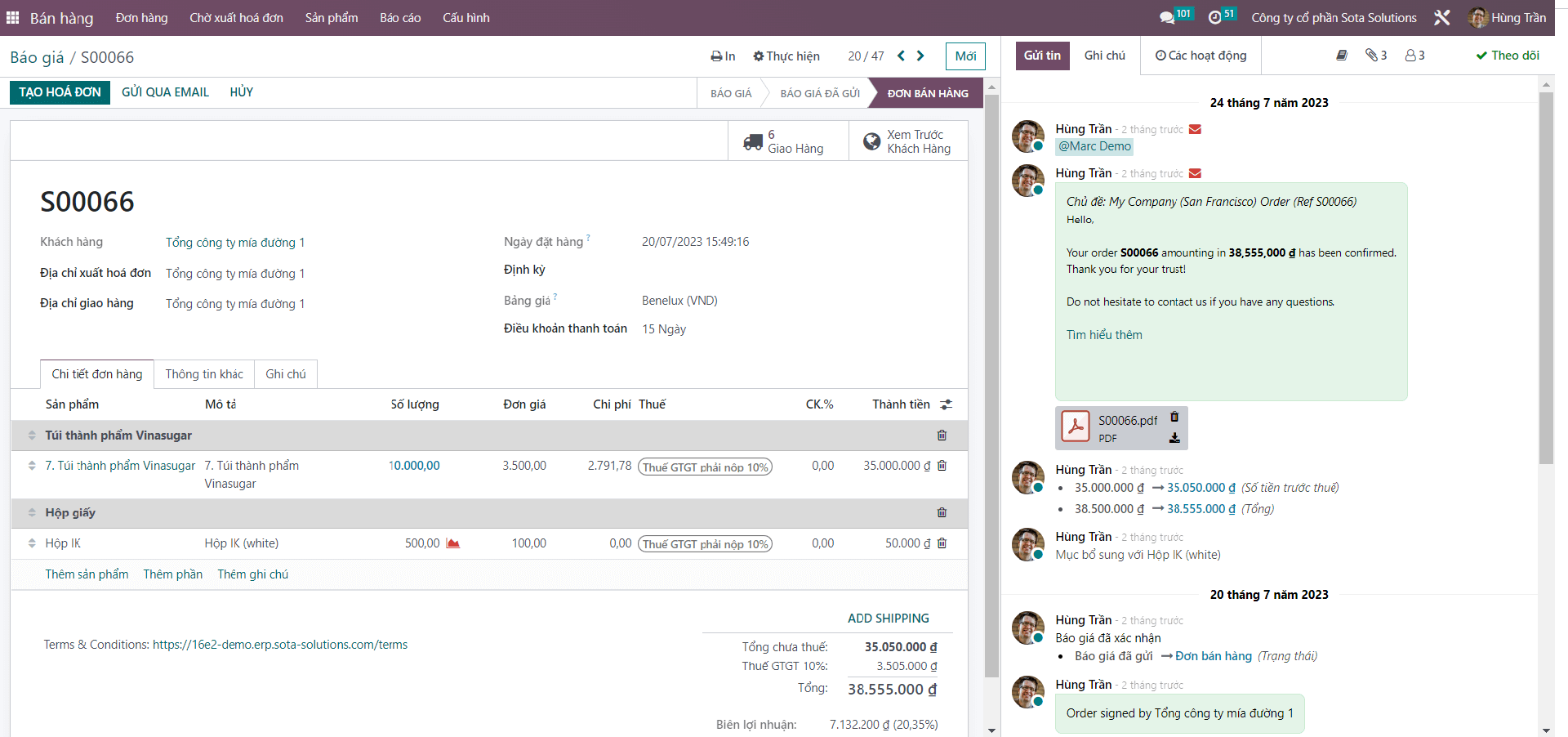

Quotation but not just a quotation!

Everything you need to create a quotation for your customers:

- Customer's information

- Quotation's information

- Product status, product pricing, product cost, margin

- Approve quotation

- Send by email to customers

- Customer can sign e-quotation online

- Convert to sale orders, manufacturing orders and delivery orders

- Create invoices

Thanks to integration between every modules, you can have every information you need to quickly create a quotation without having to ask other departments. That will save time and arise your customers' experience

Manufacturing

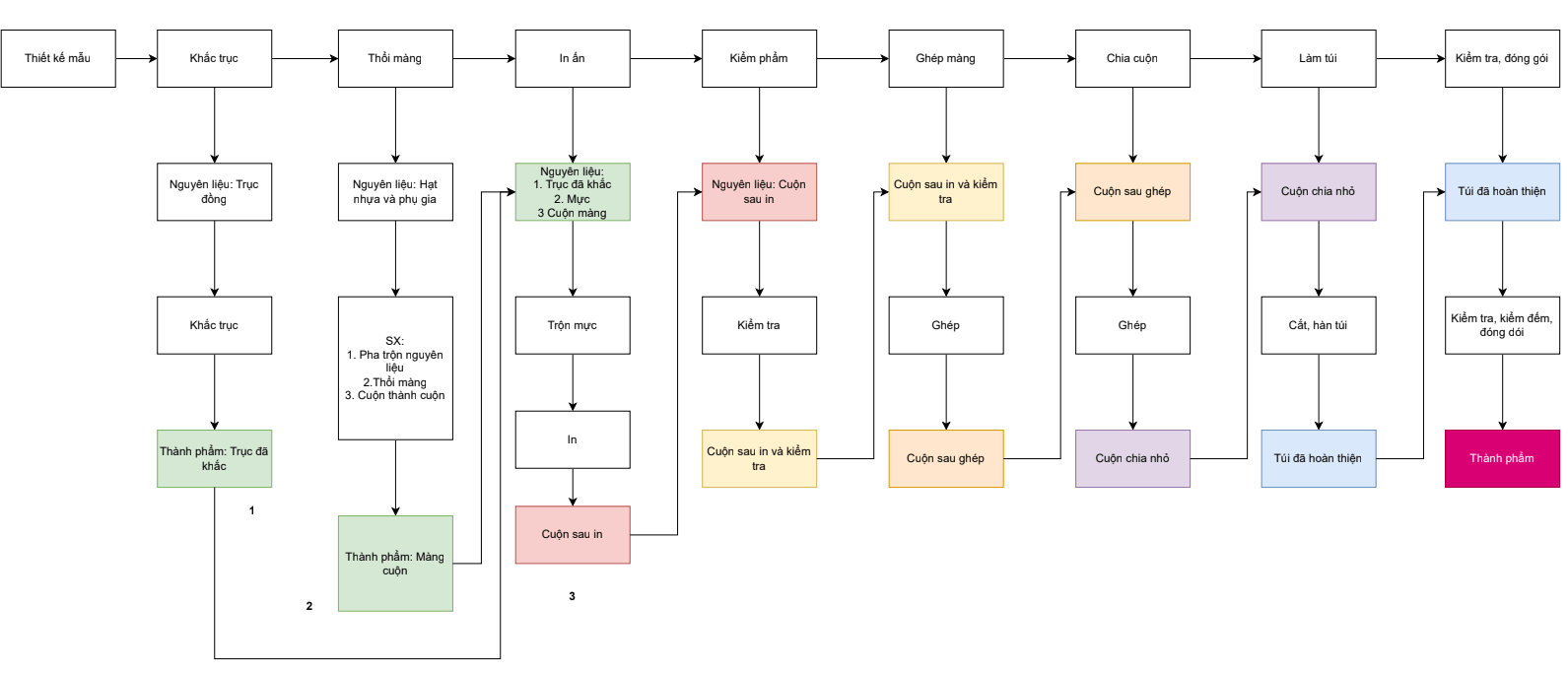

We know deep down that packaging manufacturing is one of the most complicated production process which includes plenty of small procedures to create final products. Even, the process is not similar from this type of product to another.

Let's see how we deal with that!

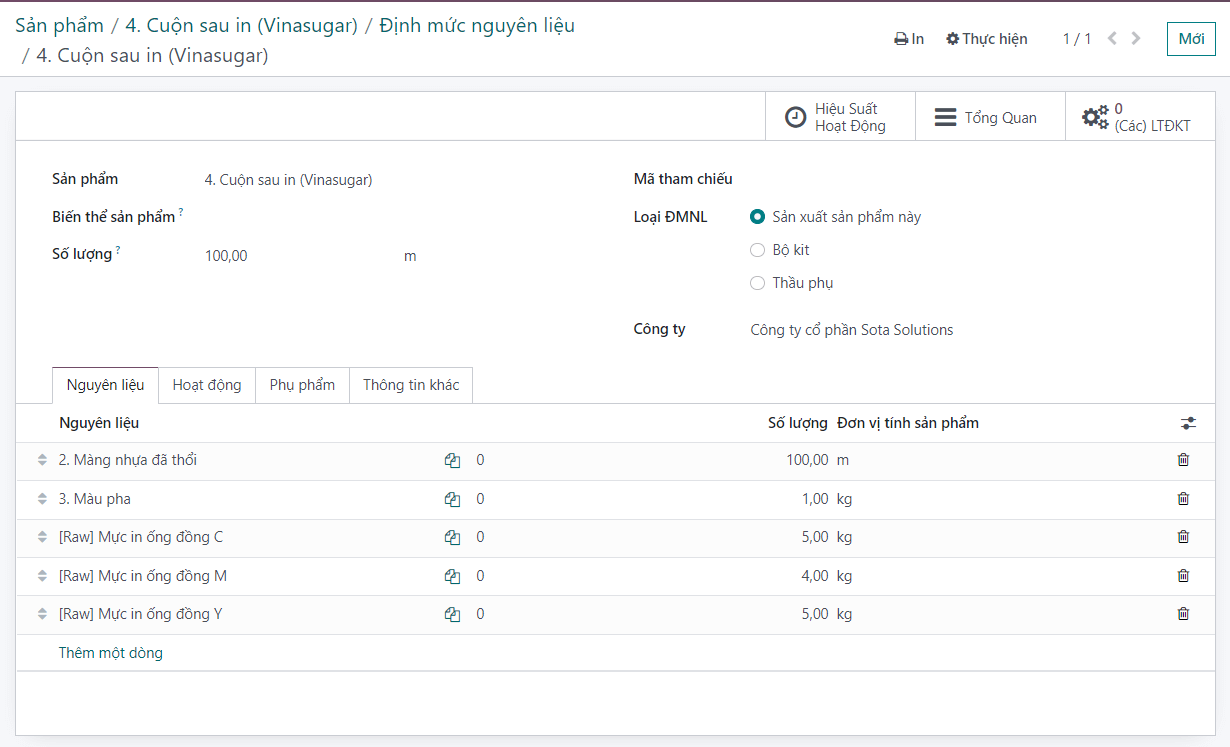

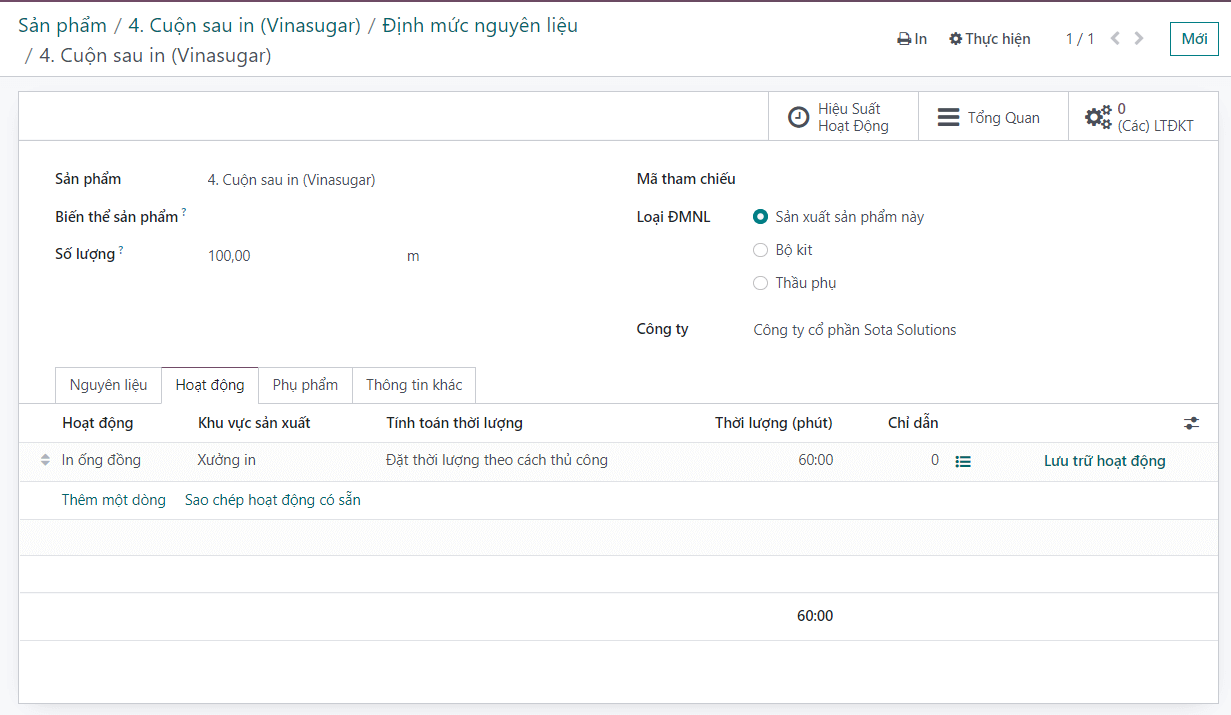

Production process and BOMs

To deal with complicated products, the very first important step is to define exactly production process and their bills of materials.

- Define over all production process for final products and semi-finished products

- Define all raw materials

- Define all production process and production zone (Who will occupy what process)

Sale Orders -> Manufacturing Orders

ERP is an integrated system that can help you automate your process from one department to another without manual operation and talks.

Once the quotation is confirmed by your customers, you can validate it can convert it to a sale order. At this moment, the system will create a delivery order, a purchase order or a manufacturing order based on inventory status of products in your quotation.

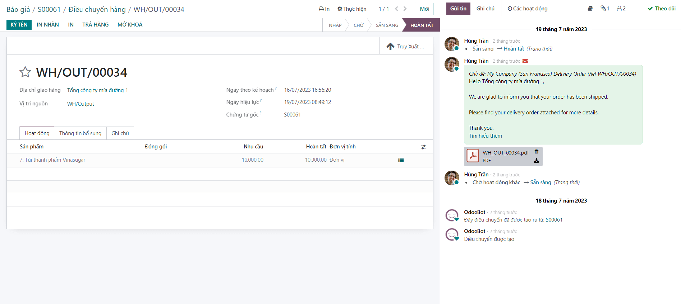

Delivery order

A delivery order will be created once the quotation is confirmed. You can see the requirement of the delivery order and the inventory status. When every product in the delivery order is ready, you can execute the shipping action by just scanning barcode on products.Discover Inventory

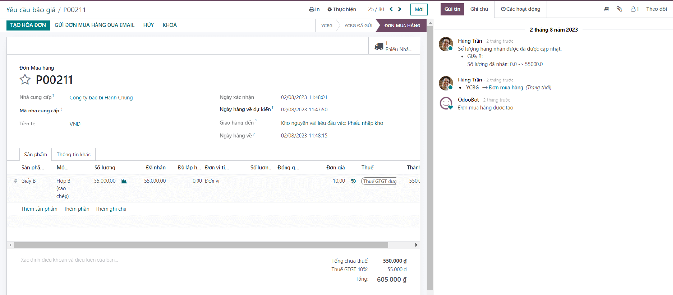

Purchase Order

A Purchase order is created if required raw material for manufacturing is not available on your stock or under minimum stock.

You can send request for quotation to your vendors through system and confirm PO. It will also create a input receipt for raw materials.

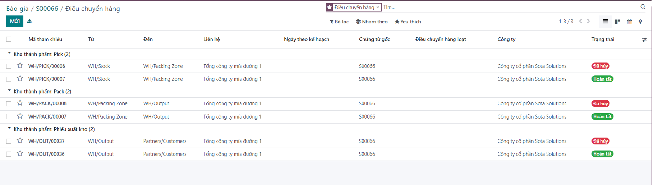

Internal transfer

Raw materials and semi-finished products will be transfer internally in your company during production. These internal transfer orders can be created automatically in the system.

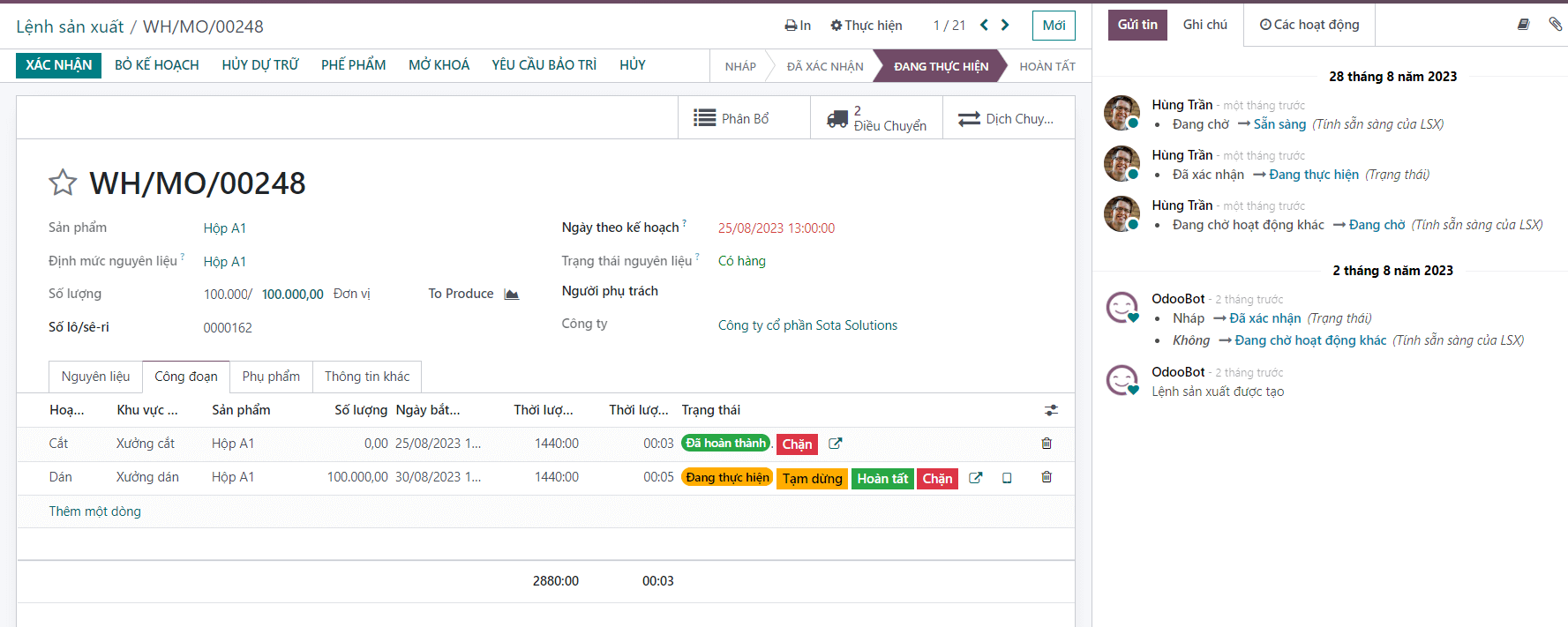

Manufacturing Order

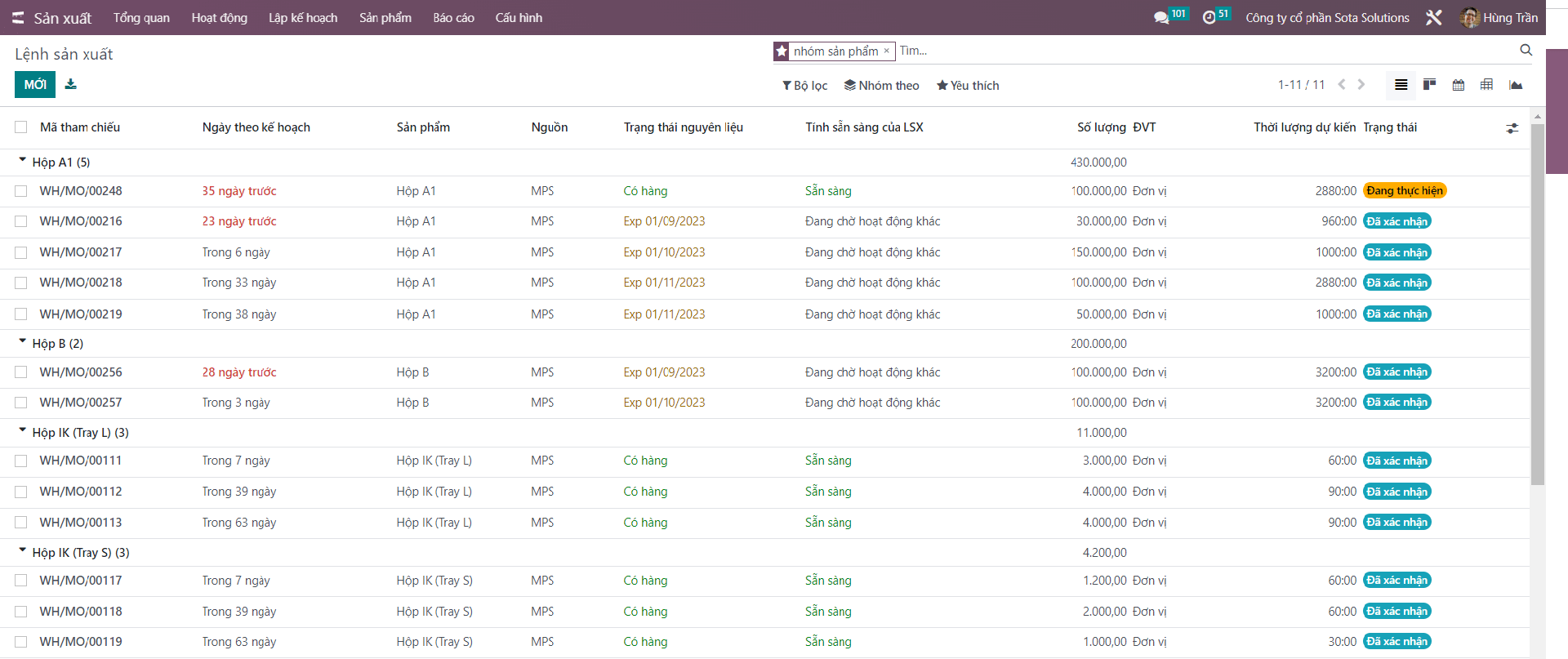

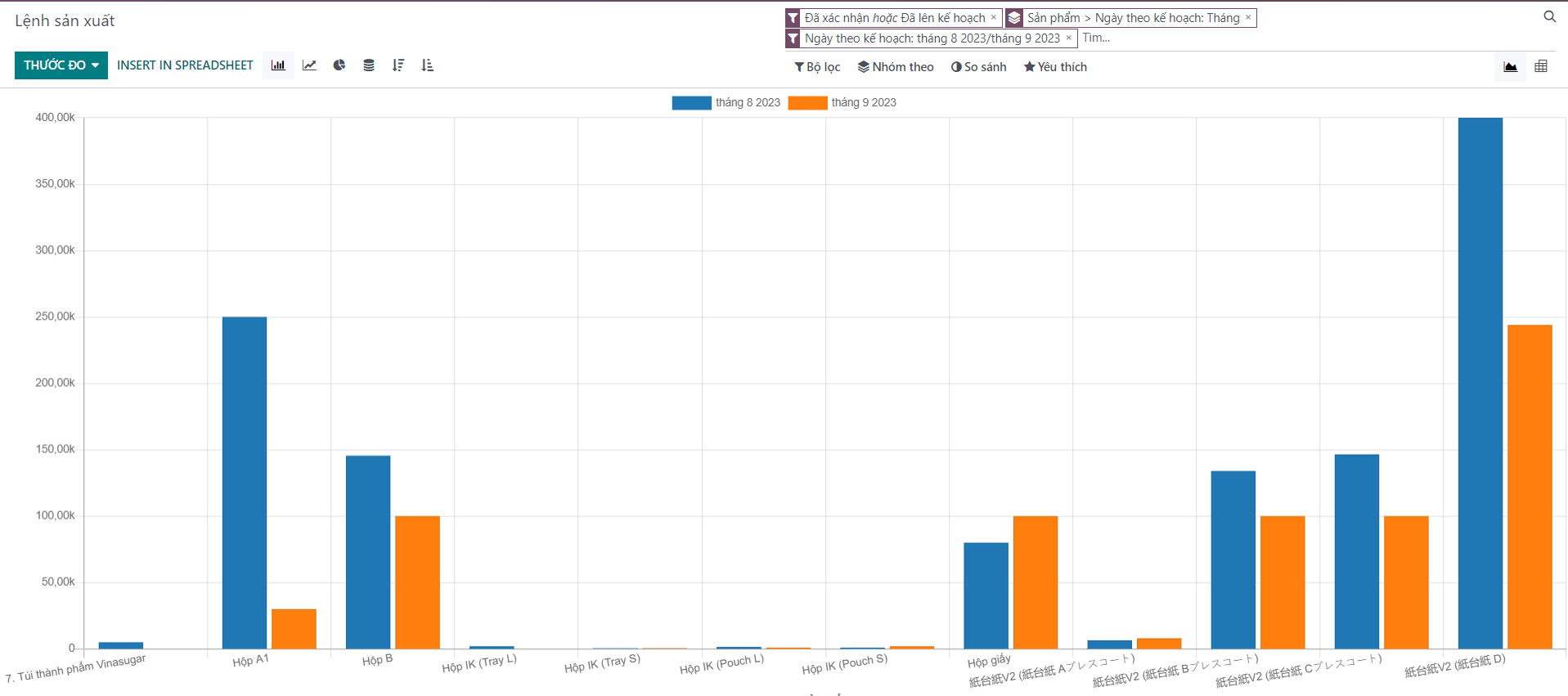

Manufacturing orders are created when finished products in your stock are not available for delivery. They can be created by master schedule planning that you plan before. In the managements view, you can see MO by day, material status, MO status, timing and other necessary information.

You can click through to view detail of a manufacturing order

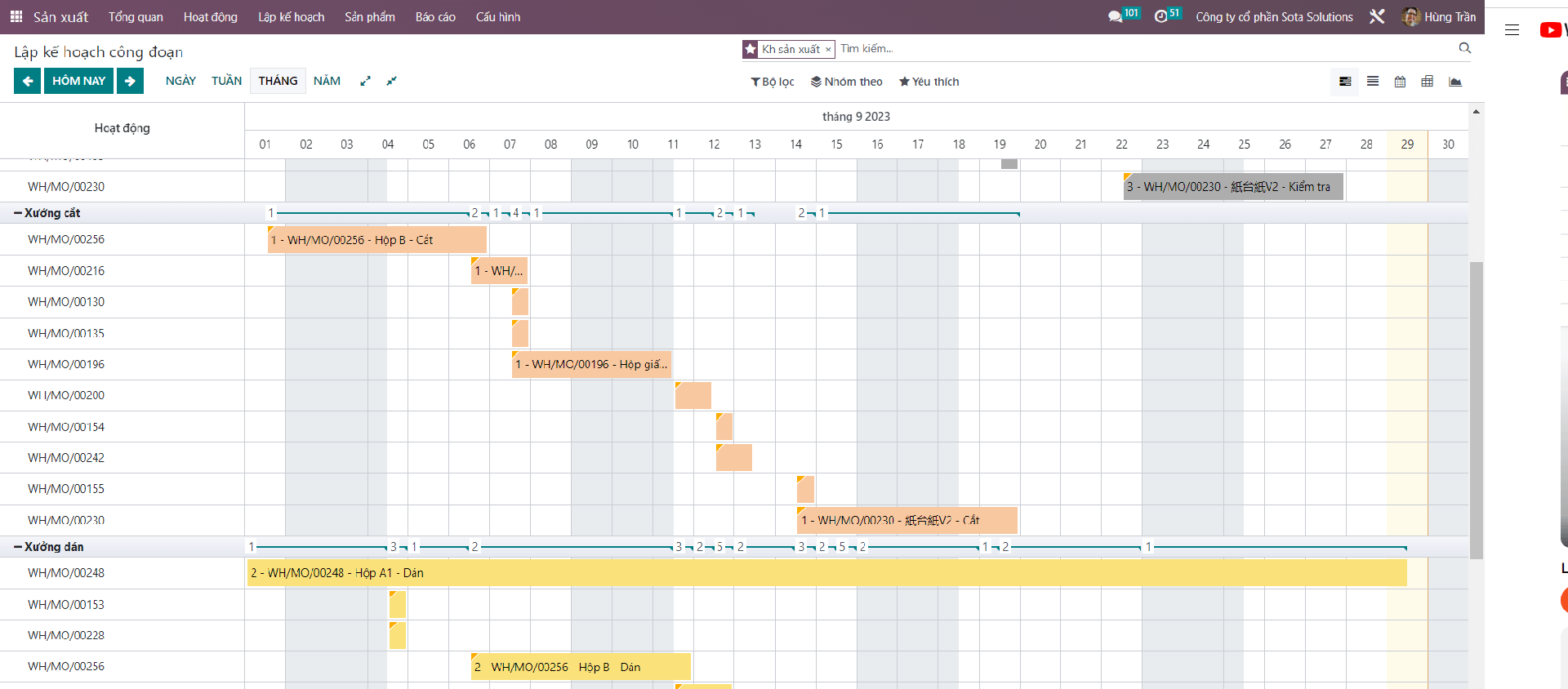

Manufacturing plan by work orders

As a manager, you can see every work orders that in under production, ongoing, in the future by this Gantt chart.

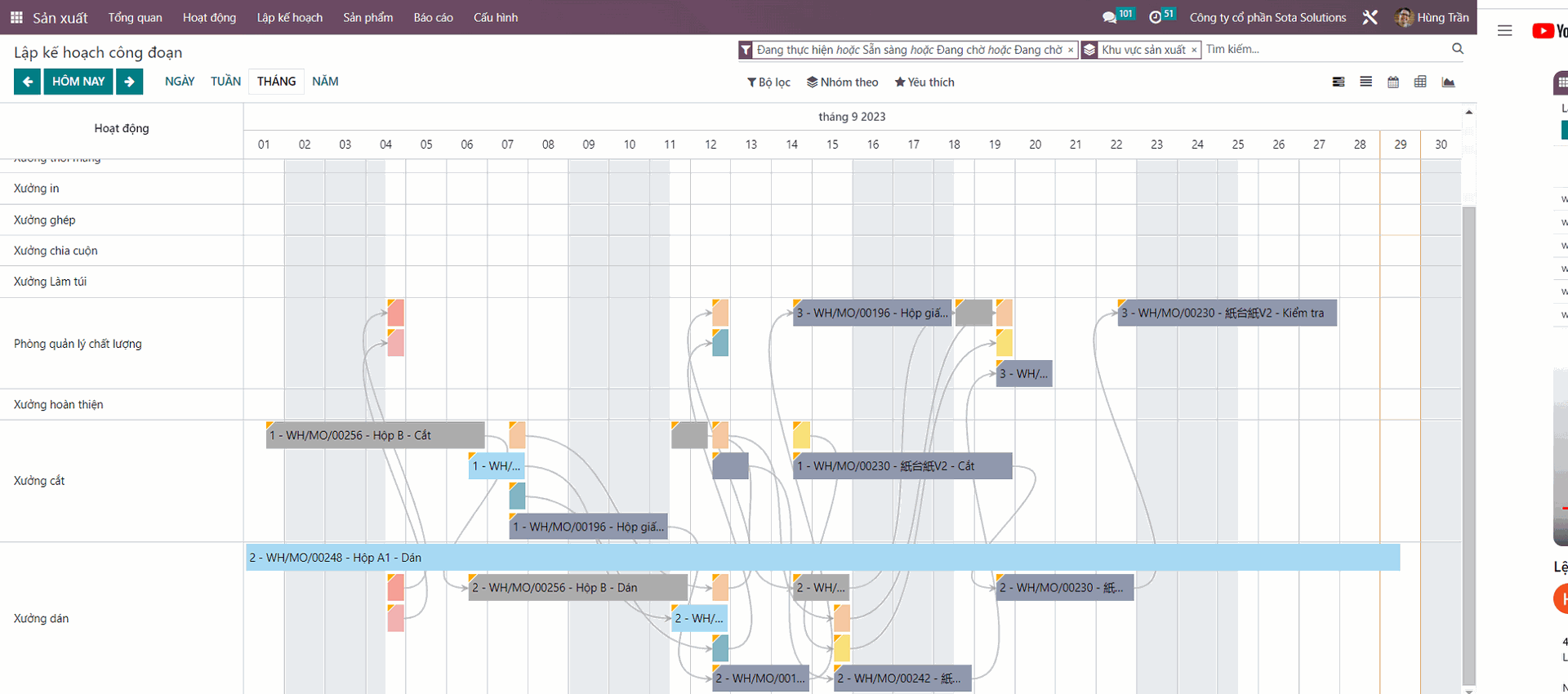

Manufacturing plan by work stations

You can also view work orders by work stations to know at that moment which stations are on duty, which is not so that you can have adjustment to maximize your resources.

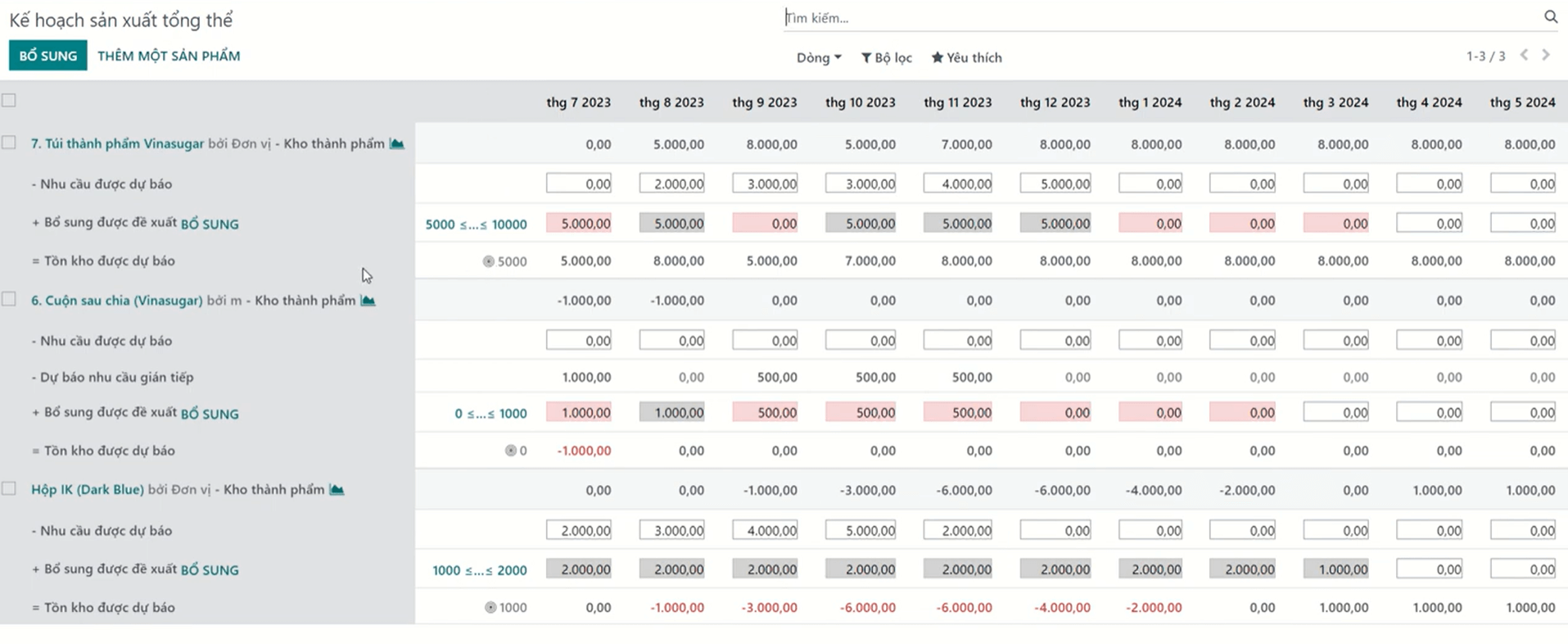

Beside sale orders, you can also schedule production plan by time to make sure that you have enough products for your customers, especially for close customers whom you will supply regularly. By that way, you can also estimate necessary materials for production without being passive.

By using dynamic charts and analysis in the system, you can know exactly your business to give decision regarding material purchasing, machine repair...

Packaging is becoming one of the most important supporting industries of Vietnam in upcoming years thanks to many free trade agreement that Vietnam has been a participant and changes in world wide supply chain. Vietnamese packaging companies have great opportunity to boost their business.

Unleash your growth potential

No credit card required