Barcode technology has become an important tool in warehouse and supply chain management. Using barcodes helps track goods, control inventory, and enhance the delivery process. In particular, automation via barcodes saves time and reduces errors compared to manual data entry. In this article, we will dig deeper into the concept of what barcodes are, how they work, and the benefits of barcode system for warehouse

I. What is a Barcode?

Barcode is a set of parallel black and white lines affixed to product packaging. In addition, below each barcode there are numbers, this is a series of numbers that businesses use to distinguish business codes, service codes and products.

Barcodes are read by smart technology devices like barcode scanners and barcode readers. When scanned, they provide information about the product that the manufacturer allows users to see, such as the brand name, origin of manufacture, product dimensions, batch information, quality inspection details, ...

The importance of Barcoding in Warehouse Management Systems

Warehouse management systems (WMS) are crucial for the success of any business, enabling improved inventory control and smoother operational processes. Nevertheless, numerous organizations face challenges with inefficient inventory and warehouse management caused by inaccurate transactions and labor-intensive manual tracking. Implementing barcoding and scanning systems can significantly enhance efficiency in this issue.

The Power of Barcode Scanning Technology

Using barcode scanning technology offers significant benefits in shipping, receiving, replenishment, picking, and packing operations. By giving each rack, container, or item a unique identifier, businesses can leverage barcoding and scanning systems to seamlessly manage the transfer of goods between different locations both within and outside a warehouse.

Barcoding allows workers to conduct inventory counts, verify order details, and optimize picking and storage tasks efficiently. This saves significant time compared to manual data entry and ensures that business leaders always have accurate and current information on inventory.

II. Types of Barcodes

As noted earlier, there are two basic types of barcodes. Here are the basics on each and key differences:

Linear/1D

Linear barcodes, also known as 1D barcodes, are the typical image that comes to mind when people think of barcodes—consisting of black vertical bars with numbers beneath them, commonly seen on products in stores. These barcodes encode numbers, letters, and symbols that correspond to specific information stored in a database, such as product name, type, size, and color. To work effectively, a 1D barcode must be associated with a database. Linear barcodes are frequently used on consumer products, loyalty cards, shipping labels, and books.

Matrix/2D

Matrix or 2D barcodes can store additional information, including quantity, images and website URLs. A 2D barcode can render this information without any connection to a database. Common uses of 2D barcodes are QR codes, which may direct users to a specific website or act as digital boarding passes. They have also become increasingly common in high-value manufacturing environments that require detailed tracking of parts and products, like medical equipment and pharmaceuticals.

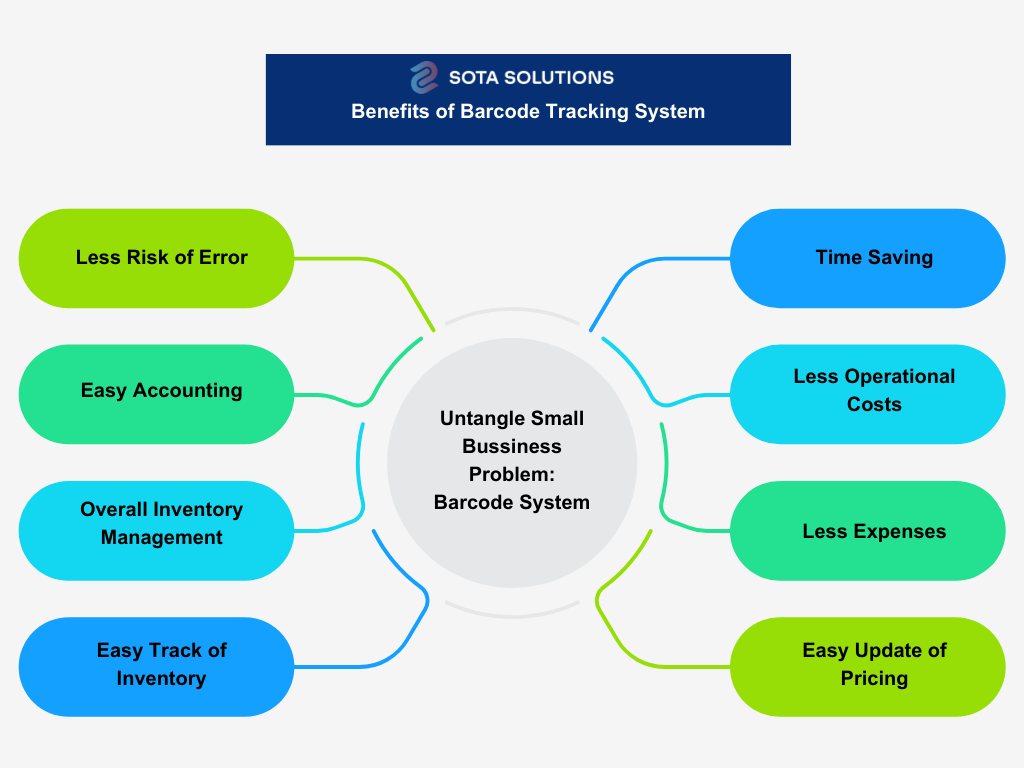

III. 8 Benefits of Barcode System for Warehouse

Reduced Error Risk:

Manual data entry into computer systems is prone to inaccuracies due to potential mistakes like pressing the wrong keys when tracking a package or contacting a customer, posing significant risks. Implementing barcode systems can significantly mitigate these errors.

Time Efficiency:

Manual data entry is time-consuming, whereas technology today emphasizes efficiency. Barcoding saves time by eliminating the need for manual data entry—information is stored simply by scanning barcode tags.

Lower Operational Costs:

Barcoding has become popular partly because it reduces equipment costs. After an initial investment in machines and equipment, ongoing costs mainly involve repair, management, and maintenance. Over time, this results in more accurate data that aids in expense evaluation.

Cost Savings:

Accurate data from barcoding facilitates better expense management. For instance, overestimating inventory quantities or costs due to inaccurate assumptions can lead to unnecessary expenses.

Simplified Pricing Updates:

Changing prices traditionally involves labor-intensive tasks like updating price tags on products and shelves. Barcodes simplify this process by allowing price information to be displayed directly on barcode tags, reducing the time and effort needed for price updates.

Efficient Inventory Tracking:

Barcode systems streamline inventory tracking—simply scanning the barcode tag provides detailed product information from manufacturing to distribution, enhancing efficiency.

Comprehensive Inventory Management:

Beyond tracking, barcodes enable additional activities such as adding details, scheduling machinery maintenance, and tracking shelf life. This comprehensive system enhances business profitability.

Streamlined Accounting:

Barcode systems facilitate accounting needs by updating data seamlessly from manufacturing to distribution units. This includes equipment maintenance, pricing updates, and other details—all accessible through scanning barcode tags, making accounting more efficient and manageable.

IV. Conclusion

The barcode system is highly beneficial for any business, particularly for small and medium businesses. It improves profitability by minimizing data errors, simplifying maintenance and accounting processes, and boosting productivity and sales.

Implementing a barcode tracking system can eliminate inefficiencies within organizational sectors, leading to improved data accuracy and real-time insights, ultimately enhancing overall business operations.