Regularly assessing your business is crucial for staying on the path to success. Inventory management is a vital aspect of your operations.

How effective has your small business been in managing its inventory? Have you consistently stocked the right products? Have stockouts caused you to miss out on sales opportunities? Or have you suffered losses due to excess inventory?

In this guide, we explore inventory management strategies, highlight key features to consider when choosing inventory management software, and share best practices for monitoring your stock levels and adapting to changes in supply and demand.

I. What is Inventory management?

In any business, inventory management plays a crucial role in achieving the organization's goals. The management of inventory is essential to ensure that a business has the right products in stock at the right time to meet customer demands. It also helps to avoid overstocking, which can lead to increased costs due to storage, handling, and obsolescence. On the other hand, understocking can result in lost sales, dissatisfied customers, and damage to the company's reputation. Therefore, it is vital to maintain optimal stock levels to maximize profits, minimize costs, and enhance customer satisfaction.

Here are some key points to consider when dealing with inventory management:

The first step in inventory management is accurately forecasting product demand. By analyzing sales data, market trends, and historical information, businesses can estimate demand with precision. This enables adjustments to stock levels, ensuring the availability of the right products when needed. For instance, if a store expects increased demand for umbrellas during a rainy season, it should raise its stock levels accordingly.

Maintaining optimal stock levels is a balancing act. The goal is to have enough stock to meet customer needs without overstocking. Overstocking can tie up capital and lead to higher storage costs, while understocking can lead to lost sales and dissatisfied customers. Therefore, businesses need to set optimal stock levels by considering factors such as lead time, demand variability, and safety stock.

Achieving the best stock levels can be done through the adoption of inventory management tools like Enterprise Resource Planning (ERP) systems. These systems utilize up-to-date data to control inventory levels, monitor sales, and track stock movements. They also streamline ordering and replenishment procedures, minimizing the chances of both stock shortages and excess inventory. For instance, a business can employ an ERP system to monitor product sales and trigger automatic restocking orders when inventory levels dip below a specified threshold.

Inventory turnover reflects how quickly a business sells and replaces its stock. A high turnover indicates efficient sales, while a low turnover may signal slow sales or overstocking. Businesses can boost turnover with sales promotions and marketing strategies to drive product demand.

Effective inventory management optimizes stock levels, cuts costs, and boosts customer satisfaction. By forecasting demand, setting optimal levels, using inventory systems, and managing turnover, businesses reach their goals for inventory and long-term success.

II. Understanding Optimal Stock Levels

Accurate inventory management is vital for business success, ensuring you avoid shortages, cut costs, and meet customer demand. Finding the right balance, known as the optimal stock level, can be challenging but crucial. Utilizing tools like ERP systems can simplify this process and lead to efficient inventory management.

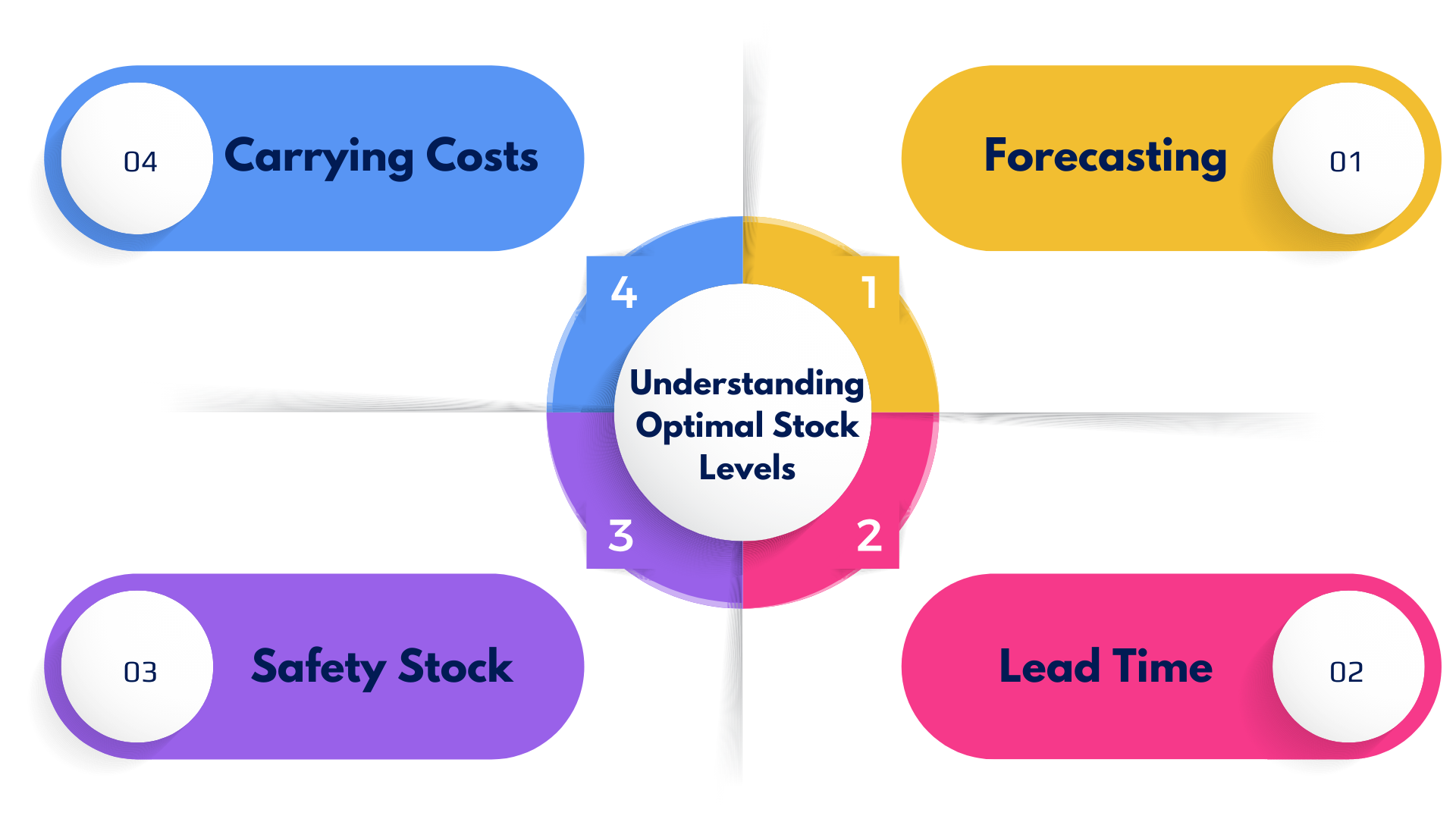

Here are key strategies for understanding and achieving optimal stock levels:

- Forecasting: Use historical data and trends to predict future demand, facilitated by ERP systems.

- Lead Time: Factor in the time from order placement to receipt to ensure adequate stock coverage.

- Safety Stock: Maintain extra inventory to safeguard against unexpected demand or supply delays.

- Carrying Costs: Consider expenses associated with inventory holding, like storage and insurance, to strike a balance between meeting demand and avoiding overstocking.

III. How SotaERP Systems Can Help?

Common inventory management challenges like overstocking, out-of-stocks, and inaccuracies significantly impact costs and revenue. Businesses should address these issues to attain optimal inventory levels. Utilizing tracking software, fostering supplier relationships, setting safety inventory levels, conducting audits, and staff training are key solutions. Moreover, Enterprise Resource Planning (SotaERP) systems offer valuable assistance by enhancing visibility, streamlining processes, and mitigating the risk of stockouts, thus supporting businesses in achieving optimal inventory levels effectively.

1. Greater Visibility

One of the primary benefits of using an SotaERP system for inventory management is the increased visibility it provides. In addition, SotaERP allows businesses to track inventory levels in real-time, providing accurate and up-to-date information about stock levels, locations, and movements. This data helps identify trends and informs decisions on when and how much to reorder. For instance, noticing a product's high sales enables adjusting stock levels to meet demand effectively.

2. Streamlined Processes

Another key benefit of using SotaERP system for inventory management is the ability to streamline processes. By automating many of the tasks associated with inventory management, such as order processing and stock tracking, businesses can reduce the time and effort required to manage their inventory. This can help to free up staff time and resources, allowing them to focus on other tasks that are more critical to the success of the business. Additionally, by streamlining processes, businesses can reduce the risk of errors and inaccuracies in inventory tracking, which can have a significant impact on stock levels and customer satisfaction.

3. Minimized Risk of Stockouts

Finally, SotaERP systems can help businesses to minimize the risk of stockouts, which can have a significant impact on customer satisfaction and the bottom line. By providing real-time visibility into inventory levels and automating order processing, SotaERP systems can help businesses to ensure that they always have enough stock on hand to meet demand. Additionally, by tracking sales patterns and demand trends, SotaERP systems can help businesses to identify potential stock shortages before they occur, allowing them to take proactive measures to prevent stockouts from happening.

IV. Key Features of SotaERP Systems for Inventory Management

Inventory management is crucial for businesses handling goods, overseeing stock levels, ensuring product availability, and managing the supply chain. While manual methods were once prevalent, the rise of technology has popularized Enterprise Resource Planning (ERP) systems for this purpose.

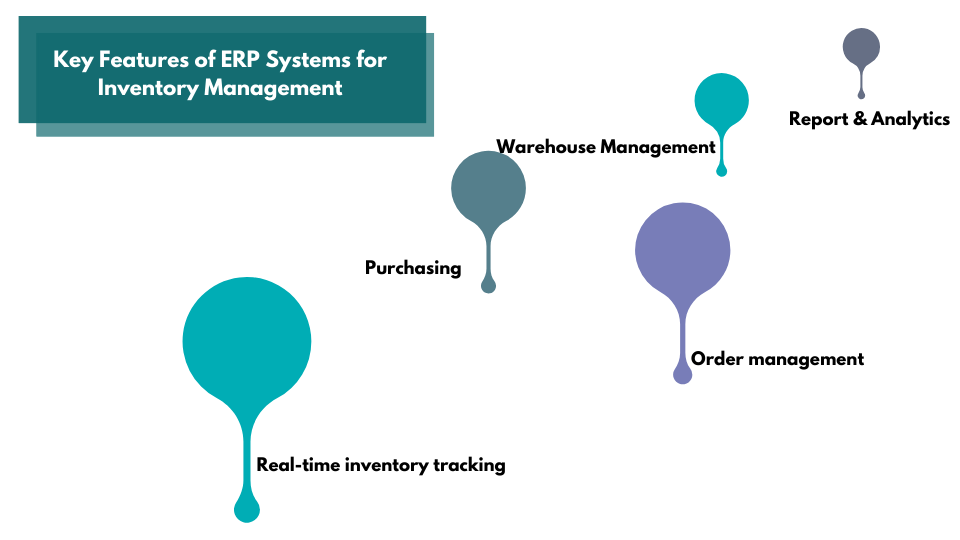

SotaERP system offers a centralized platform for inventory control, automating tasks like order processing and stock management. This automation saves time and minimizes errors. Key features include:

1. Real-time inventory tracking: SotaERP systems provide real-time visibility into inventory levels, allowing businesses to track stock levels across multiple locations and make informed decisions about stock replenishment.

2. Order management: SotaERP systems automate the order management process, from order placement to fulfillment. This includes order processing, picking, packing, and shipping. By automating this process, businesses can reduce errors and improve order accuracy.

3. Purchasing: SotaERP systems provide tools for managing the purchasing process, including supplier management, purchase order creation, and invoice processing. These tools help businesses streamline the purchasing process and reduce costs.

4. Warehouse management: SotaERP systems provide tools for managing the movement of goods in and out of the warehouse. This includes inventory tracking, stock location management, and order fulfillment.

5. Reporting and analytics: SotaERP systems provide reporting and analytics tools that allow businesses to track performance metrics, such as inventory turnover, order fulfillment rates, and supplier performance. These insights help businesses make informed decisions about inventory management and identify areas for improvement.

V. Conclusion

The SotaERP system stands out as the premier choice for manufacturers and distributors due to its emphasis on focused manufacturing and distribution activities, user-friendly interface, powerful inventory management, optimized manufacturing processes, robust supply chain management capabilities, and scalability. This ERP solution enables businesses to streamline operations, enhance inventory and production efficiency, boost supply chain visibility, and drive overall efficiency in the highly competitive manufacturing and distribution sector.

If you have any questions, please contact us immediately for further advice.

Leave us a message