The Freight Forwarding industry is facing many challenges in managing complex processes and requiring high accuracy.From order receipt (Ordering) to invoicing and payment processing (Billing), everything requires seamless coordination between multiple departments and systems. However, manual processes and lack of coordination between departments often lead to errors, wasted time, and additional costs.

With the rapid development of technology, automating processes with specialized ERP systems has become a breakthrough solution for the Freight Forwarding industry. The ERP system helps automate the steps in the process, minimize errors, optimize workflows, and enhance business efficiency.

In this article, we will explore how ERP can address these issues, helping freight forwarding businesses save time, reduce errors, and enhance customer service efficiency.

1. Current situation and challenges of traditional Ordering and Billing processes

In many freight forwarding businesses today, the process from when a customer places a booking (ordering) to when payment is completed (billing) still operates in a fragmented, manual, and disconnected manner. This leads to a series of problems:

1.1 Manual data entry – prone to errors, time-consuming

- Booking data is often manually entered from emails, Excel files, or through various departments.

- Repeating the task of entering information at different stages (booking → bill of lading → charge calculation → invoice generation) causes errors to occur frequently.

Consequences: information errors, delays, impacting customer trust.

1.2 Information not synchronized between departments

- Sales, Operations, Finance, and Customer Service often use different systems or work via email/Excel.

- The lack of a central system causes delays or inaccuracies in updating order status, freight charges, or payment status.

Consequences: loss of control over information flow, difficulty managing efficiency, customers not being updated in a timely manner.

1.3 Complex charge calculation, easily confused

- Calculating charges based on various factors such as route, cargo type, Incoterm conditions, time-based surcharges, etc., requires high accuracy.

- Without an automated system, errors are very likely to occur – especially with surcharges or schedule changes.

Consequences: disputes with customers, revenue leakage, or the need to rework invoices.

1.4 Delayed invoice generation – impacts cash flow

- When there is no interconnected process between operations and accounting, invoices are often issued many days late or lack information.

- Manual document reconciliation makes it difficult for accounting to review before issuing invoices.

Consequences: payment delays, reduced cash flow, impacting financial planning.

1.5 Lack of transparency and traceability

- When processes are not synchronized, it is very difficult to trace back bill of lading information, quotations, or reasons for past charge changes.

- Managers lack a real-time overview of operational efficiency.

Consequences: loss of control, difficulty making quick and accurate decisions.

2. Overview of the Ordering to Billing Process in Freight Forwarding

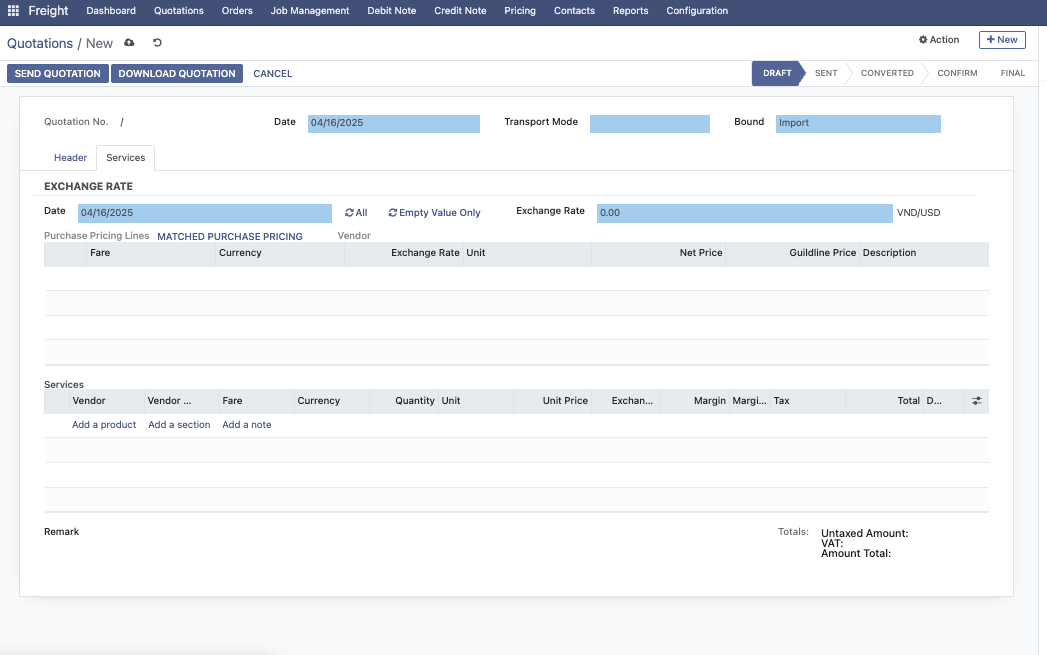

2.1 Booking request reception (Ordering)

- Customers submit booking requests via email/portal (FCL, LCL, AIR…)

- Sales or Customer Service receives and reviews the request and provides a freight quotation.

- Once the customer agrees → a booking is created on the system. Output: booking information is created → transferred to the dispatch department.

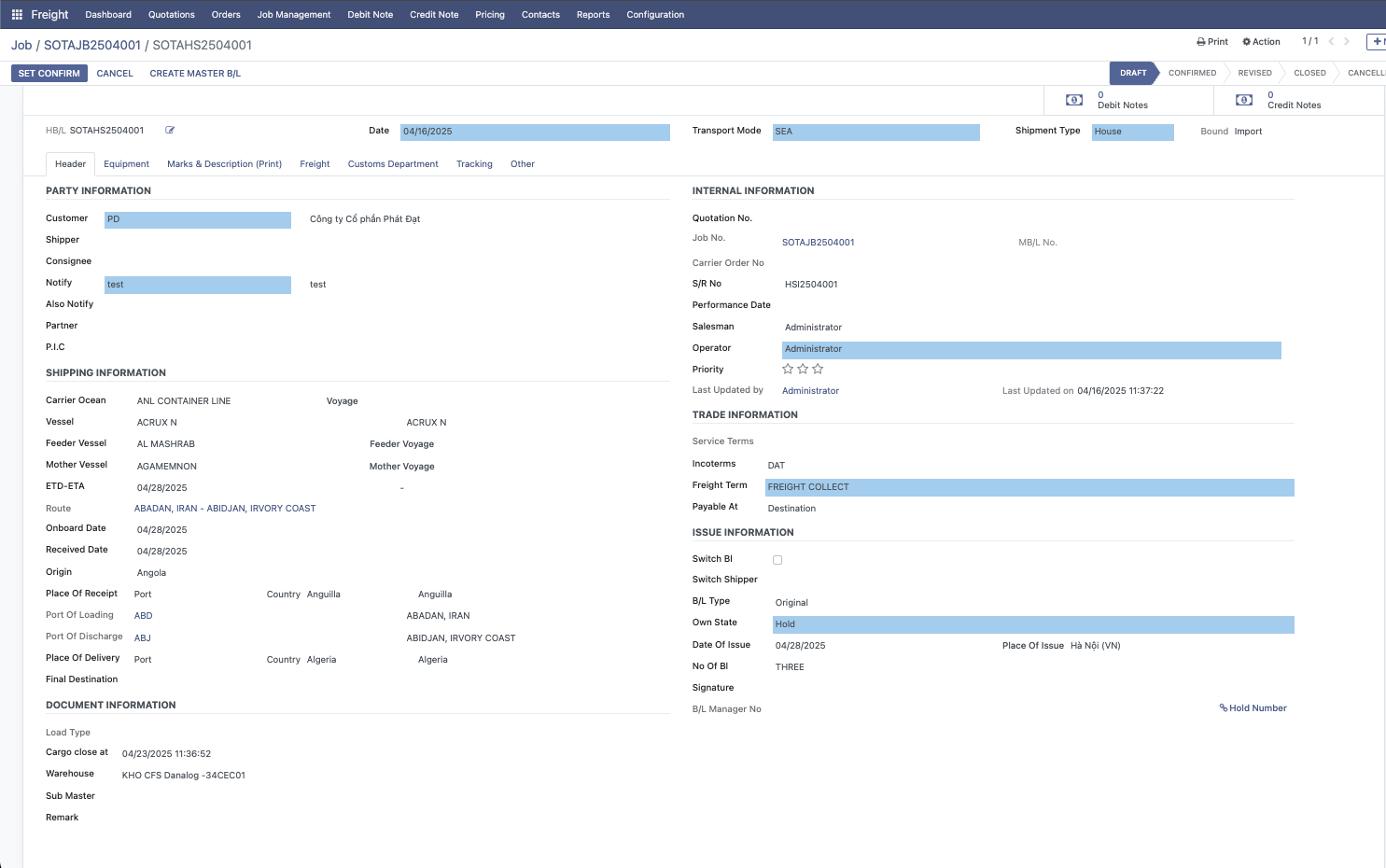

2.2 Dispatch & shipment preparation

- The OPS department handles: making bookings with shipping lines/airlines, arranging containers, coordinating cargo pickup.

- Updating bill of lading status (Pickup, CY Cut-off, ETD, ETA…).

- Preparing/finalizing documents: HBL/MBL, Invoice, Packing List, CO…

Output: shipment is in operation, data is continuously updated for relevant departments.

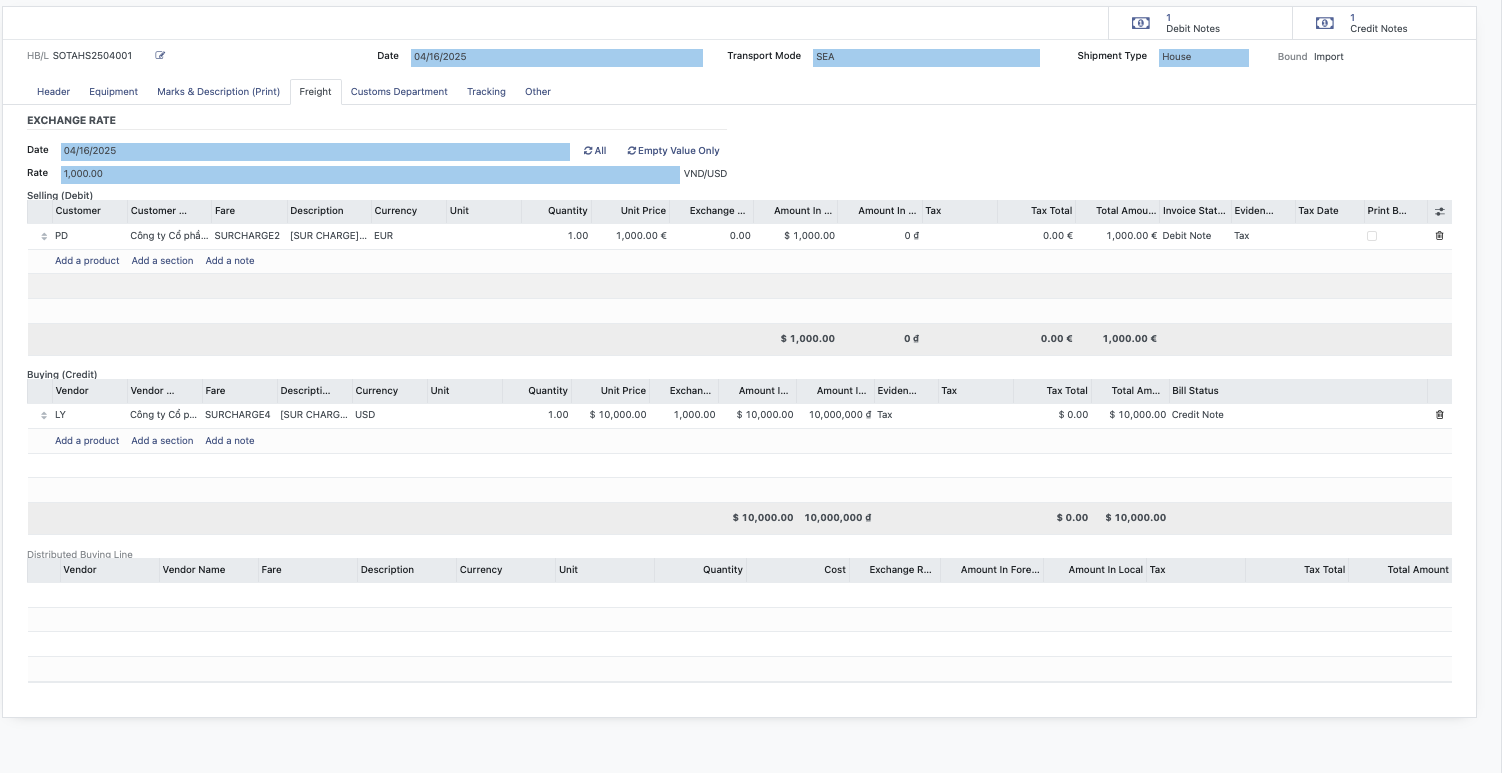

2.3 Rating & costing

- Based on negotiated price lists or system tariffs.

- Calculating the total freight charges including: freight, local charges, handling, port charges, surcharges…

- Reconciling with actual costs from vendors (shipping lines, trucking…).

Output: profit margin for each shipment is determined, preparing for the invoicing step.

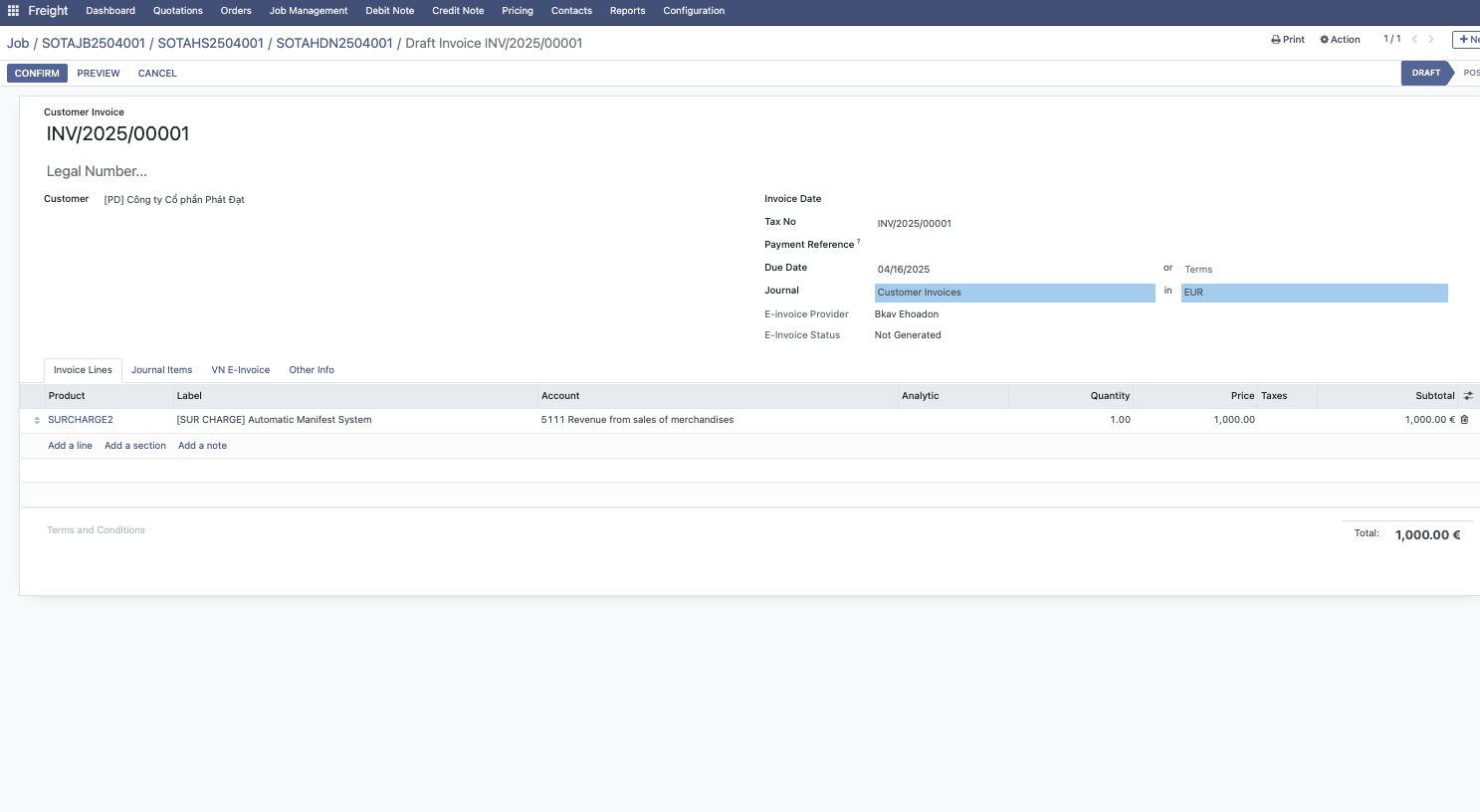

2.4 Invoice generation (Billing)

- Once the shipment is completed, the accounting department (or the ERP system automatically) generates an invoice for the customer.

- The invoice may include multiple items: freight charges, surcharges, collection and payment on behalf (if any).

- Synchronization with the financial system or electronic invoicing.

Output: invoice is sent to the customer, the payment collection process begins.

2.5 Accounts receivable tracking & payment collection

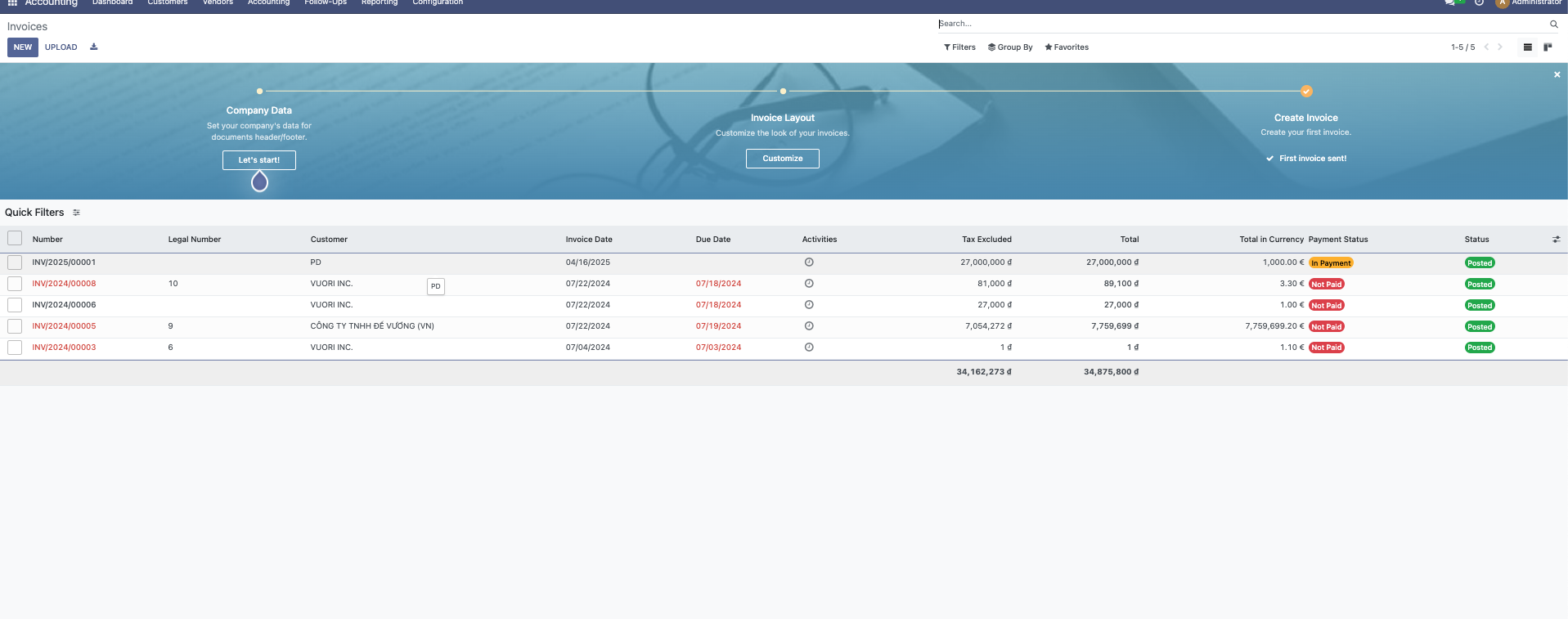

- Accounting tracks payment status through ERP.

- Sending payment reminders/automatic alerts if overdue.

- Calculating net profit after all expenses.

3. The power of ERP in automating the Ordering and Billing process

3.1 End-to-end automation – no more repetitive manual data entry

- From the booking request, the system automatically generates shipment codes and circulates data across departments without the need for re-entry.

- Information such as routes, cargo type, price terms, transit times, etc., is synchronized from the beginning → avoiding errors.

3.2 Seamless connection between sales – ops – accounting

- Sales creates the booking → Ops receives complete information → Accounting calculates charges & generates invoices based on bill of lading data.

- No more "information silos" or circulating Excel files.

3.3 Automatic calculation of freight and surcharges based on pre-set tariffs

- The ERP system applies tariffs, route-based pricing, peak season surcharges, etc.

- Based on weight, route, and shipping conditions → ERP automatically calculates accurate and transparent charges.

3.4 Fast, accurate, and financially integrated invoice generation

- Immediately after shipment completion, ERP automatically aggregates costs → generates invoices (or sends them to the accounting system).

- Minimizes errors, missing or late invoices → accelerates payment collection.

3.5 Real-time tracking, easy control of accounts receivable & profitability

- Managers can quickly view total revenue and profit per shipment, transport route, or customer.

- Accounting tracks payment status in real-time – no outstanding debts are overlooked.

4. Benefits of operating on an integrated ERP System

4.1 Saves processing time

- Eliminates repetitive manual data entry between departments.

- Reduces order processing time, charge calculation, and invoice generation.

- Faster order processing → increases the ability to take on new orders.

4.2 Reduces errors and information loss

- Data is synchronized throughout the process, preventing loss between steps.

- Accurate freight charges, surcharges, and bill of lading information from the outset.

- Minimizes invoice errors → avoids disputes with customers.

4.3 Accelerates payment collection and improves cash flow

- Invoices are generated quickly immediately after the bill of lading is finalized.

- Real-time accounts receivable tracking → easy to send reminders and control payment timelines.

- Helps the finance department forecast cash flow more accurately.

4.4 Transparency & control over the entire process

- Management has an overall view of order progress, revenue, and profit per shipment.

- Automatic real-time reports → support rapid decision-making.

- Easy to review any order, document, or invoice with just a few clicks.

4.5 Enhances customer experience

- Fast response times, clear information, easy tracking.

- No more errors in charges or invoices → increased customer trust.

- Increases customer retention and the development of loyal customers.

4.6 Ready to connect to new Technologies: eInvoice, E-Docs, Tracking, CRM, AI...

- Integrated ERP allows businesses to expand their system without having to "tear down and rebuild."

- Easy to connect with customs declaration systems, electronic quotes, or other financial and accounting software.

5. Steps to implement ERP for automating the Ordering and Billing process

5.1 Assess business needs and objectives

- Define primary objectives: Automate the Ordering and Billing process, increase accuracy, reduce errors, and accelerate processing speed.

- Analyze the current process: Evaluate the strengths and weaknesses of the existing process (manual, fragmented).

- Identify requirements: Include necessary ERP features such as automatic charge calculation, invoice generation, and data synchronization between departments.

5.2 Choose the right ERP solution

- Select ERP software: Choose an ERP solution suitable for the logistics industry, capable of fully integrating functions such as booking management, charge calculation, bill of lading management, invoice generation, and accounts receivable tracking.

- Note on customization capabilities: The ERP software should be adaptable to the company's specific needs, such as configuring price lists, ancillary fees, and various documents in Freight Forwarding.

- Consider integration features: The ERP should be able to integrate with external systems such as e-invoicing systems, electronic customs declarations, CRM, and financial tools.

5.3 Prepare data and configure the system

- Collect and standardize data: Including customer information, freight rates, shipping fees, bill of lading documents (HBL/MBL), etc. This data needs to be standardized and entered into the ERP system.

- Configure the ERP system: Set up modules for each department (Sales, Ops, Finance) and connect functions such as:

- Booking Process: Automatically generate waybill numbers and update shipping status.

- Rating and Costing Process: Configure price lists and costs based on routes, weight, etc.

- Invoice Generation Process: Automatically aggregate fees and generate invoices for customers.

5.4 Train and transfer knowledge to employees

- Train employees: Ensure all employees in Sales, Ops, and Finance are trained on the ERP system and how to use each function.

- Provide guidance materials: Issue detailed documentation and instructional videos for employees to easily refer to when needed.

- Test the system: Conduct testing before official implementation to ensure everything works correctly.

5.5 Run trials and verify processes

- Test the system with real data: Execute the Ordering and Billing process from start to finish, monitoring the system's handling of each step.

- Verify the accuracy of charges and invoices: Ensure the system correctly calculates freight charges, surcharges, and generates accurate invoices.

- Check connectivity: Ensure Sales, Ops, and Finance departments can access information seamlessly.

5.6 Official implementation and performance monitoring

- Officially launch the ERP system: After completing the testing steps, officially implement the ERP system into the operational process.

- Monitor performance: Measure KPIs such as order processing time, invoice accuracy, number of errors, and customer satisfaction.

- Optimize the system: Continuously monitor and improve the ERP process if any issues arise during operation.

5.7 Long-term maintenance and support

- Update and upgrade the system: Ensure the ERP system is always updated with new features and meets the evolving needs of the company.

- Provide user support: Offer a technical support team to resolve any issues that arise after implementation.

6. Conclusion

In a highly competitive and accuracy-demanding Freight Forwarding industry, automating the entire process from Ordering to Billing using an ERP system is not just a breakthrough, but also the foundation for sustainable development and optimized business efficiency.

Adopting integrated ERP helps logistics businesses not only minimize the risk of errors and data entry mistakes but also enhances coordination between departments, saving time and costs. More importantly, the automated process helps businesses improve cash flow, accelerate payment collection, and increase customer satisfaction through accurate and timely invoice generation.

By optimizing the Ordering and Billing processes, businesses not only enhance internal efficiency but also build a significant competitive advantage. ERP is a powerful tool that transforms manual processes into smoother, easier, and more accurate workflows, while also opening up opportunities for long-term growth as the scale of operations expands. Contact us for consultation and receive free materials on the latest technology trends.