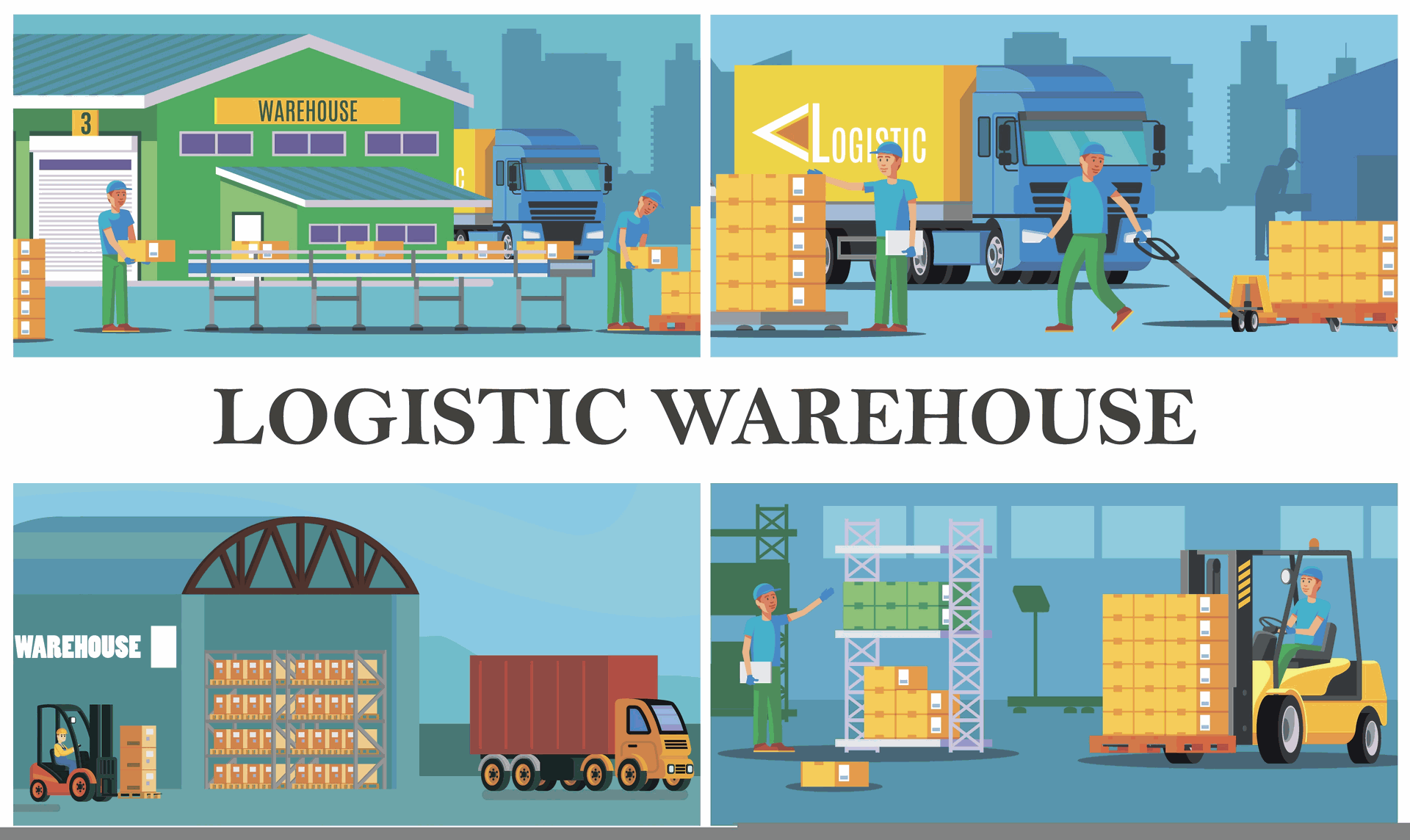

The boom in e-commerce, the demand for rapid delivery, and the need for transparency in the supply chain are making warehousing a decisive factor in the business efficiency of many enterprises. However, as the volume of goods rapidly increases, traditional warehouse models, which rely on manual labor, consume high energy, and lack connectivity, are starting to show signs of overload. Businesses not only face difficulties in inventory control but also bear significant pressure from operating costs and the demand for optimizing customer experience.

Furthermore, the global trends of sustainable development, ESG standards, and Net Zero commitments are creating a strong imperative compelling businesses to restructure their warehousing operations towards being green, smart, and energy-efficient. In this context, the sustainable warehouse is no longer an experimental option but has become a strategic direction that helps businesses operate more effectively and meet international standards.

Thanks to the support of modern technology such as IoT, artificial intelligence, Warehouse Management Systems (WMS), autonomous robots, and renewable energy, sustainable warehouses offer the capability for real-time inventory control, reduced emissions, minimized errors, and maximized cost optimization. Businesses pioneering early conversion are creating a superior competitive advantage and building supply chains that are more resilient to market fluctuations.

This article will help you understand the nature of the sustainable warehouse, why this model has become an inevitable trend, and the steps businesses can take today to gradually build a smart, green, and sustainable warehousing system in the technological era.

1. What is Sustainable Warehousing?

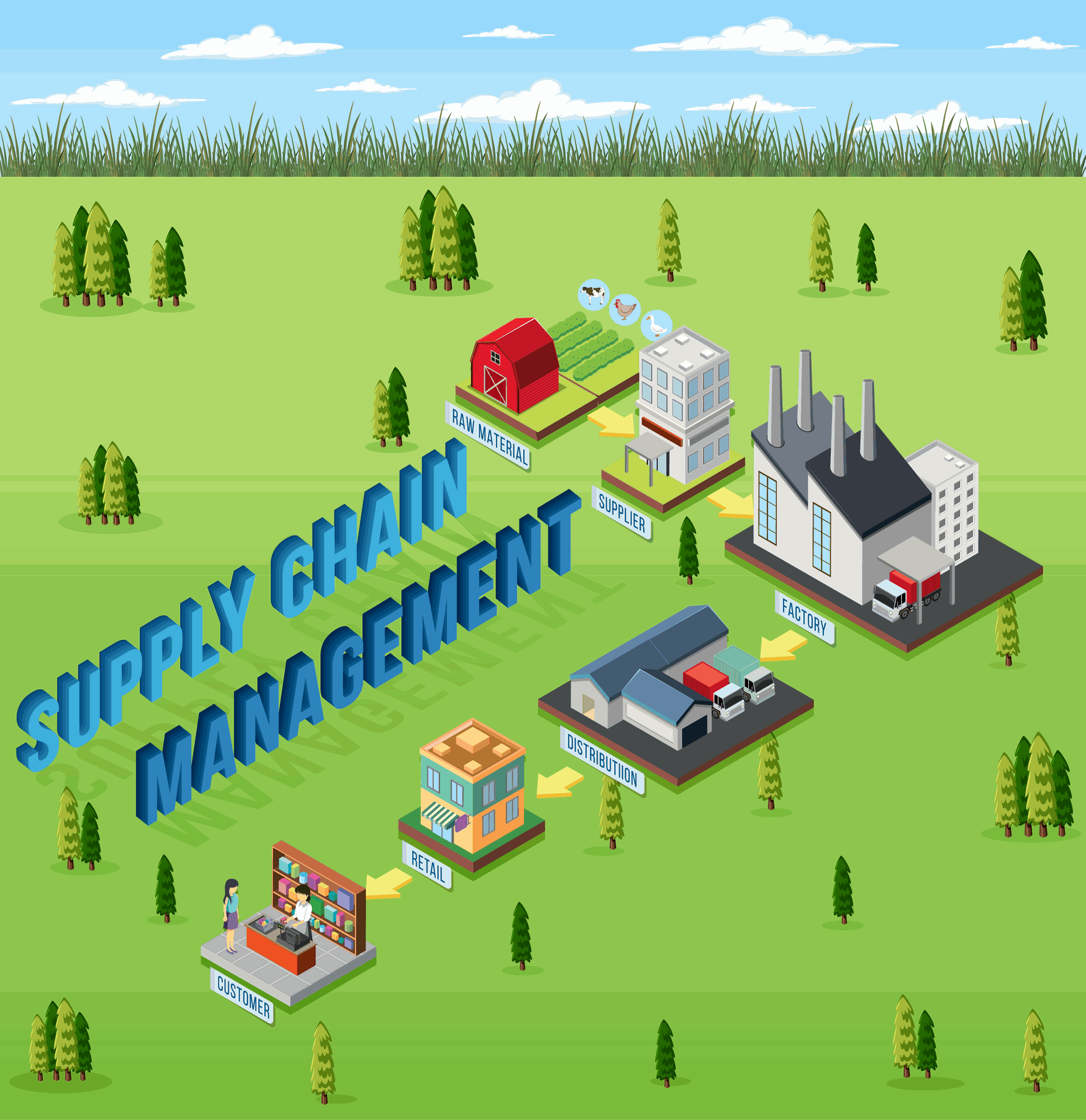

Sustainable Warehousing is a warehouse operating model designed and managed to optimize efficiency, save energy, reduce emissions, and apply technology to ensure long-term development for the business. Instead of relying on manual processes and consuming a lot of resources, sustainable warehousing adopts smart solutions like digitalization, automation, IoT, renewable energy, and eco-friendly materials to operate more efficiently while minimizing environmental impact.

A sustainable warehouse typically includes the following elements:

- Smart design and layout to optimize space and goods movement flow.

- Efficient energy use such as LED lights, light sensors, and solar energy.

- Digitalized operating processes (WMS, FMS, IoT) to manage goods in real-time.

- Maximized reduction of paperwork and errors through automation and system integration.

- Optimized workforce using robots, AGVs, or smart support equipment.

- Reduced emissions and use of green materials to meet ESG and Net Zero standards.

Overall, sustainable warehousing is a combination of smart operation, resource efficiency, and environmental friendliness, helping logistics businesses enhance productivity, reduce costs, and meet the increasingly high demands of the technology era.

2. Challenges businesses face when operating traditional arehouses

- High operating costs: Traditional warehouses consume a lot of electricity, rely heavily on a large workforce, and are prone to processing errors, leading to continuously increasing operating costs.

- Manual management easily leads to inventory discrepancies: Inventory input, output, and counting using Excel or paperwork result in quantity discrepancies, difficulty controlling the flow of goods, and easy loss/shrinkage without traceability.

- Lack of real-time data: Due to the absence of a real-time monitoring system, businesses find it difficult to track performance, leading to delays when incidents occur and making it hard to make timely decisions.

- Difficulty scaling when orders increase: Manually operated warehouses cannot cope when the number of orders increases rapidly, leading to workforce overload and reduced processing efficiency.

- Inability to meet ESG requirements and the green trend: In the context where global businesses prioritize environmental friendliness, traditional warehouses consume many resources and have high emissions, making them unsuitable for modern standards.

3. Benefits of sustainable warehouses in the age of technology

- Optimized Energy – Reduced Operating Costs Sustainable warehouses utilize energy-saving solutions such as LED lighting, light sensors, smart ventilation systems, and solar energy. This allows businesses to significantly reduce electricity costs while maintaining stable and more efficient operations.

- Automation & Digitalization of Processes The application of technologies like IoT, WMS, barcodes, and robotics automates the receiving, storing, and inventory processes, reducing manual processing time by 60–70% and minimizing human-caused errors.

- Reduced Emissions – Suitable for ESG & Net Zero Sustainable warehouses prioritize reducing paper usage, optimizing internal transportation flows, and adopting environmentally friendly materials. This helps businesses comply with ESG standards and move closer to the Net Zero goal.

- Increased Accuracy & Operational Safety Thanks to smart monitoring systems and automatic alerts, businesses minimize inventory mix-ups, reduce product damage, and improve occupational safety within the warehouse.

- Enhanced Customer Experience & Competitive Advantage A sustainable warehouse enables businesses to deliver faster, provide inventory transparency, and ensure stable product quality. This not only elevates the customer experience but also creates a clear competitive advantage in the market.

4. Key technologies in the sustainable warehouse model

- IoT & Smart Sensors – Real-time Monitoring: IoT sensors continuously monitor temperature, humidity, product location, and equipment status in the warehouse. Real-time data allows businesses to detect anomalies promptly and optimize operational processes.

- WMS – Warehouse Management System: Automatically manages inbound/outbound/storage and inventory control using barcodes or QR codes, reducing manual errors and ensuring data accuracy. This is the core foundation for building a smart and sustainable warehouse.

- AI & Big Data – Demand Forecasting, Inventory Optimization: Analyzes data patterns to predict product demand, helping businesses plan optimal inventory levels. Big Data supports the identification of fast- and slow-moving items, preventing excess inventory and reducing waste.

- Robotics & AGVs – Optimized Goods Movement: Assists with moving goods within the warehouse, shortening processing time, reducing reliance on human labor, and ensuring safety. This is a crucial step towards warehouse automation.

- Renewable Energy (Solar) – Reduced Electricity Costs: Solar power systems help reduce operational costs while cutting CO₂ emissions, aligning with ESG standards and green transformation goals.

- Carbon Management System – Emission Measurement & Reporting: Carbon management tools help businesses track emissions from warehousing activities, generate transparent reports for ESG auditing, and support long-term emission reduction planning.

5. Where can businesses start the sustainable warehouse transformation?

- Assess the Current Warehouse Status and Energy Consumption: Businesses need to review their entire current warehouse system, including layout, electricity consumption levels, goods handling processes, and areas causing waste. This is the foundational step to identify priority issues for improvement.

- Digitize Processes Before Automating: Before investing in robots or automated equipment, businesses should start by digitizing data and processes: managing inbound-outbound-inventory, stocktaking, and order tracking. Digitization helps standardize workflow and creates clear data documentation for subsequent stages.

- Implement WMS or FMS to Build a Stable Data Foundation: A Warehouse Management System (WMS) or Freight Management System (FMS) should be implemented early to ensure real-time, accurate, and synchronized data across departments. This is the "backbone" of a sustainable warehouse, helping to connect with IoT, robotics, and other advanced technologies.

- Use Green Standards as the Basis for Standardization: In every step of the transformation, businesses should prioritize solutions that save energy, reduce emissions, minimize paperwork, and adopt environmentally friendly materials. This helps logistics not only be efficient but also align with ESG standards and the Net Zero trend.

6. Conclusion

The sustainable warehouse is not just a modern trend but has become an essential requirement for businesses to maintain a competitive advantage in the technology era. Transforming into a smart, energy-efficient, and eco-friendly warehouse model helps businesses optimize costs, enhance performance, and meet the market's increasingly stringent ESG standards. Starting with process digitization, implementing an ERP operational management system, and then applying IoT, AI, and renewable energy, businesses can fully build a logistics system that is both efficient and sustainable, creating a solid foundation for long-term growth. Contact us for consultation and to receive documents on the latest digital transformation trends.